The quality and yield of cashews depend largely on the shelling phase in the nut industry. To optimize this process, it is essential to know the details of different cashew shelling machines. This guide covers various types of cashew shelling machines, how they work, why they matter, and how to choose the best one for your needs.

Shelling cashews is a complex process that requires careful extraction of the nut from its shell without damaging it. Shelling techniques have evolved significantly from manual methods to modern machinery.

Why Shelling Matters: Unveiling the Delicious Nut

The quality of the cashew nut depends largely on how well it is shelled. Shelling affects its flavor, look, and price. By shelling carefully, the kernels can be preserved whole and the waste can be minimized, leading to more profits.

Traditional Methods: A Glimpse into the Past

In the past, people used manual techniques that required a lot of skill and hard work. These techniques showed craftsmanship, but they were not very productive and could not keep up with increasing needs.

The Rise of Machines: Automation Takes Over

Shelling machines transformed the cashew industry with their advent. They evolved from manual to fully automated devices, improving the shelling process with technology, and increasing productivity and yield.

1. Hand-Operated Machines: Simple and Efficient

Hand-operated machines offer simplicity and precision. They are ideal for small-scale operations, providing cost-effectiveness and ease of use. However, they are limited by their throughput capacity and are more labor-intensive.

Benefits of Hand-Operated Machines

- Precision: Allows meticulous handling, minimizing kernel damage.

- Cost-Efficiency: Lower initial investment compared to automated machines.

Drawbacks of Hand-Operated Machines

- Limited Capacity: Inability to meet high-volume demands efficiently.

- Labor-Intensive: Requires manual effort, affecting scalability.

2. Semi-Automatic Machines: The Bridge Between Manual and Automated

Semi-automatic machines strike a balance between manual and automated processes. They offer improved efficiency while maintaining some level of manual control.

Advantages of Semi-Automatic Machines

- Enhanced Efficiency: Increased output compared to manual methods.

- Controlled Operation: Allows manual intervention for precision.

Disadvantages of Semi-Automatic Machines

- Moderate Capacity: Limited scalability for large-scale operations.

- Dependency on Labor: Requires skilled operators for optimal performance.

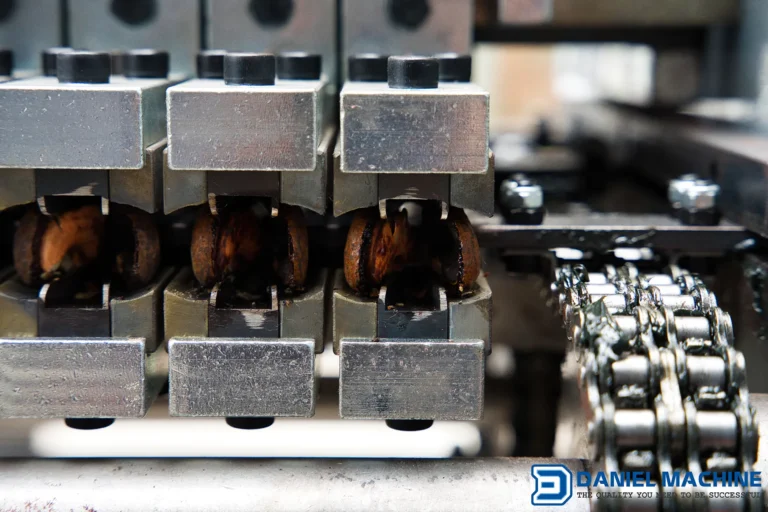

3. Fully Automatic Machines: The Pinnacle of Shelling Technology

Fully automatic machines represent the epitome of shelling technology. They offer unparalleled efficiency and scalability, catering to high-volume demands with minimal manual intervention.

Boons of Fully Automatic Machines

- High Throughput: Capable of processing large volumes swiftly.

- Minimal Labor Dependency: Reduced need for manual oversight.

Banes of Fully Automatic Machines

- High Initial Investment: Significant capital required for acquisition.

- Technical Complexity: Maintenance and repairs may demand specialized expertise.

Choosing the Right Machine: Tailoring Shelling to Your Needs

To choose the best cashew shelling machine, you need to evaluate different aspects that affect its performance.

Factors to Consider: Finding the Perfect Fit

Production Capacity: Sizing Up Your Needs

Determining the required output capacity aligns the choice of machine with operational demands.

Budget Constraints: Balancing Costs and Benefits

Considering initial investment alongside operational costs aids in optimizing ROI.

Labor Availability: Finding the Right Balance

Analyzing available labor resources helps in deciding the level of automation required.

Space Requirements: Fitting the Machine In

Space allocation for the machine is crucial for an efficient workflow.

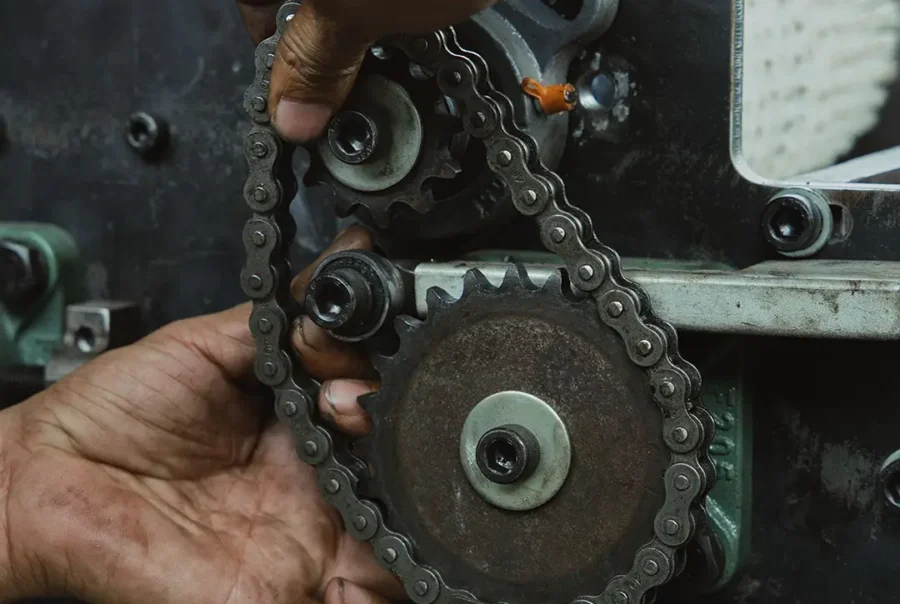

Maintaining Your Machine: Keeping Your Shelling Operation Smooth

Regular Maintenance: The Key to Longevity

Regular maintenance of cashew shelling machines is imperative for sustained performance and longevity.

Implementing a comprehensive maintenance schedule is essential for machine durability.

Cleaning and Lubrication: Essential Upkeep

Regular cleaning and lubrication prevent wear and tear, ensuring smooth operation.

Inspection and Repair: Addressing Potential Issues

Routine inspection and immediate repair of any anomalies prevent operational disruptions.

Troubleshooting Common Problems: A Guide to Smooth Operations

Addressing common issues ensures uninterrupted shelling operations.

Low Shelling Efficiency: Identifying and Fixing the Cause

Analyzing factors causing reduced efficiency aids in rectifying the issue promptly.

High Kernel Breakage: Minimizing Damage to Your Product

Implementing corrective measures reduces wastage and maintains product quality.

Machine Malfunctions: Addressing Technical Challenges

Promptly resolving technical issues prevents downtime and loss of productivity.

The Future of Cashew Shelling: Innovation and Advancement

The landscape of cashew shelling continues to evolve with emerging technologies and a growing emphasis on sustainability.

Emerging Technologies: Transforming the Industry

Technological advancements, including AI integration and robotics, promise further efficiency and precision in cashew shelling.

Sustainability and Environmental Impact: Responsible Shelling Practices

Embracing sustainable practices in shelling not only benefits the environment but also meets consumer preferences for ethically sourced products.

Conclusion: Unlocking the Potential of Cashew Shelling Machines

A good cashew shelling machine can improve the quality and efficiency of cashew processing. To achieve optimal performance and profitability, it is important to know the different types of machines and choose the one that suits your operational needs best.

Beyond Efficiency: The Broader Impact of Cashew Shelling Machines

Empowering Women and Local Communities

Creating Jobs and Economic Opportunities

Cashew processing, especially with the aid of shelling machines, generates employment opportunities, particularly in regions where cashew farming is prevalent, contributing to economic growth.

Improving Working Conditions and Safety

Shelling machines improve working conditions by minimizing hazardous manual labor, creating a safer and healthier work environment.

Supporting Sustainable Cashew Farming Practices

With increased efficiency, cashew shelling machines indirectly promote sustainable farming practices by fostering better utilization of resources and reducing waste.

Conclusion: Embracing the Future of Cashew Processing

Cashew shelling machines represent a pivotal leap in the cashew processing industry, offering multifaceted advantages that enhance efficiency, quality, and sustainability. Embracing these machines isn’t just about optimizing operations; it’s about revolutionizing the way we approach cashew processing, unlocking new opportunities, and fostering a sustainable future.