Cashew nuts are a popular and nutritious snack enjoyed worldwide. As the demand for cashews increases, businesses need efficient and reliable equipment to meet market demands. The cashew shelling machine is a crucial piece of equipment for shelling nuts. This article aims to guide business owners in choosing the right cashew shelling machine for their specific needs, considering factors such as capacity, efficiency, maintenance, safety features, and budget.

Cashew shelling machines automate the labor-intensive task of removing the outer shell from cashew nuts. Manual shelling processes are time-consuming, inefficient, and result in high labor costs. Investing in a cashew shelling machine not only increases productivity but also ensures consistent quality, reduces labor requirements, and improves profitability for cashew processing businesses.

Factors to Consider When Choosing a Cashew Shelling Machine

Selecting the right cashew shelling machine is crucial to optimizing the shelling process and maximizing operational efficiency. Consider the following factors when making your decision:

1. Capacity and efficiency

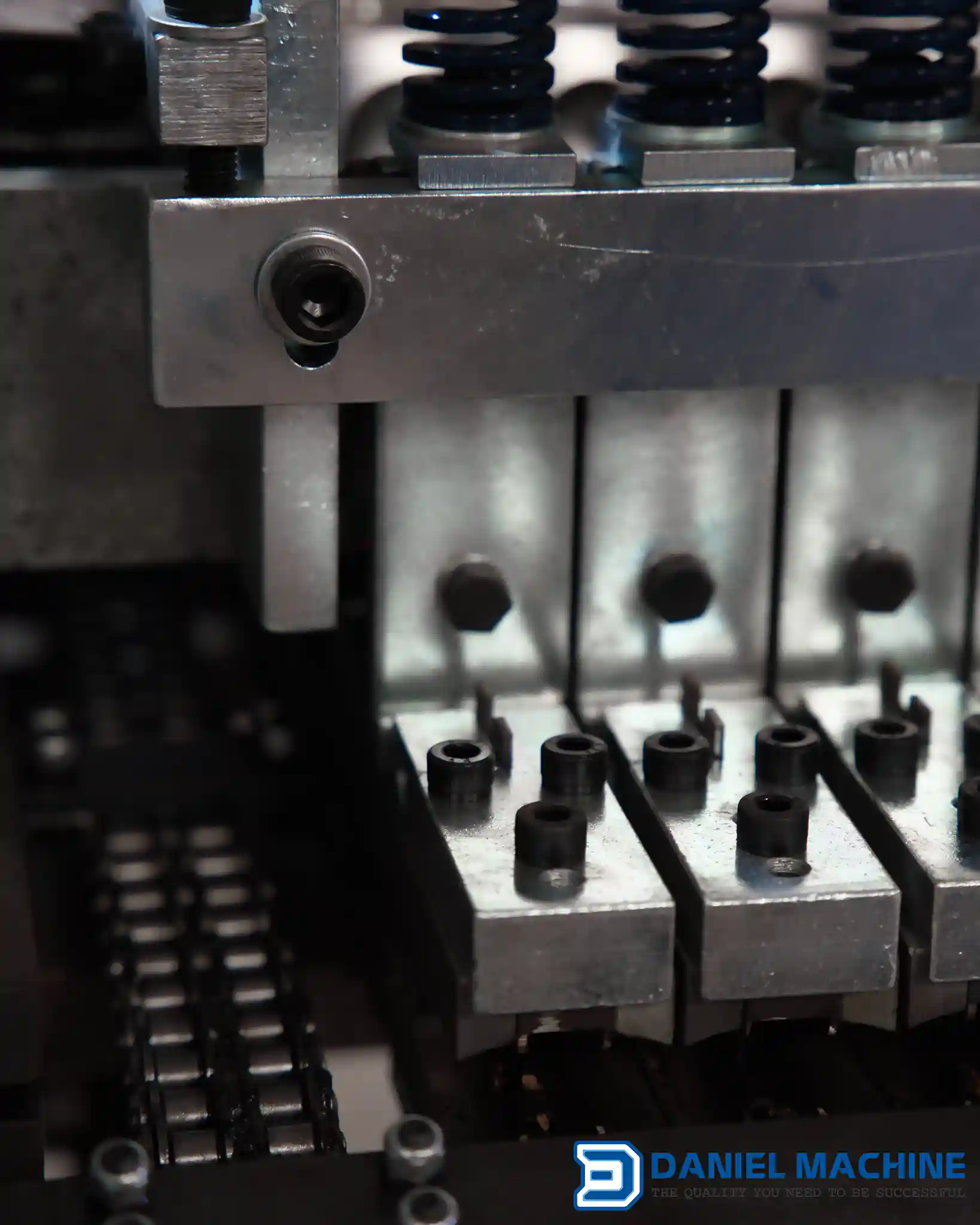

Evaluate the machine’s capacity in terms of nuts shelled per hour and choose one that aligns with your production requirements. Additionally, look for features that enhance efficiency, such as adjustable shelling mechanisms, uniformity of shelling, and minimal kernel breakage.

2. Shell Separation System

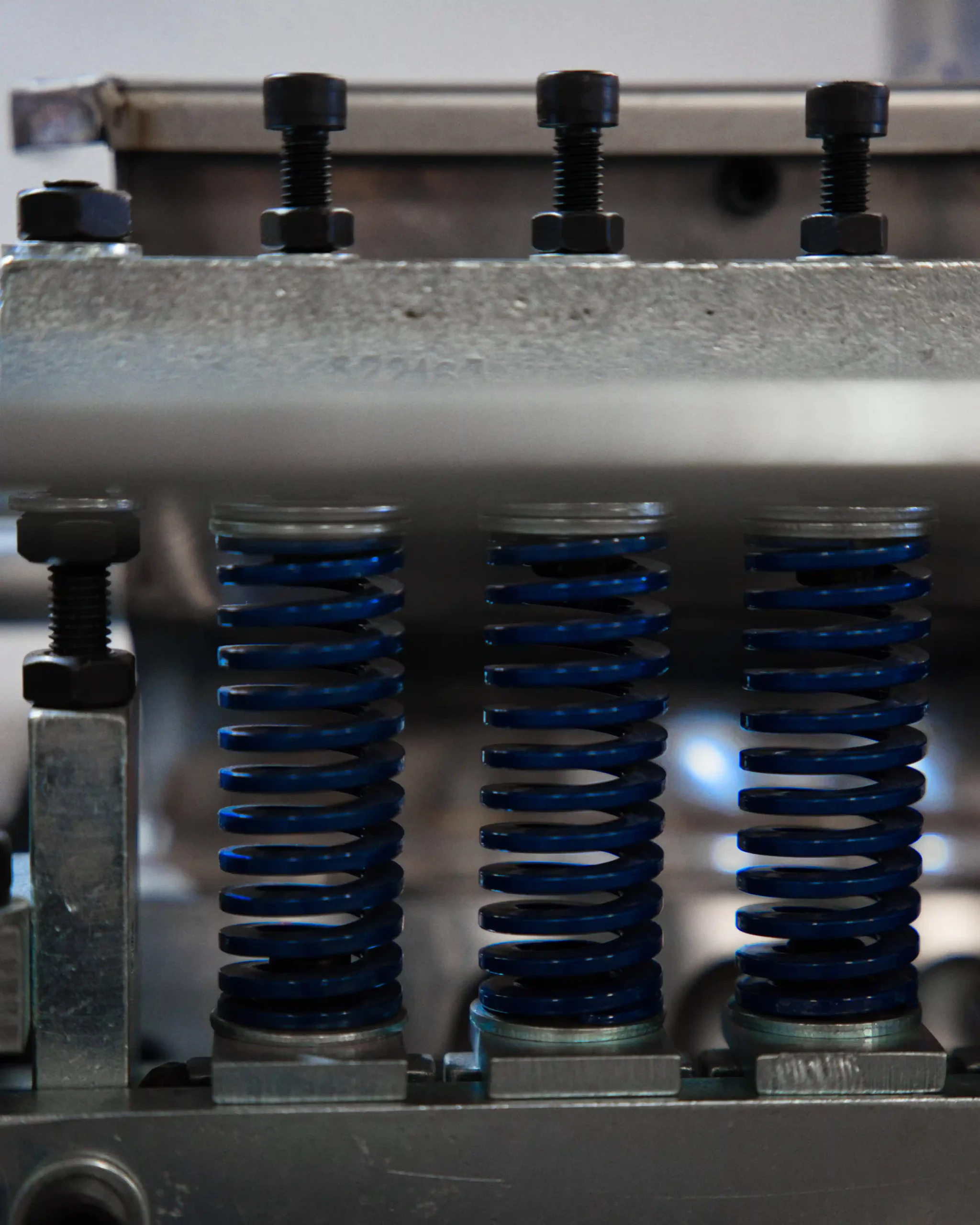

Evaluate the shell separation system of a shelling machine to ensure it effectively separates the shells without damaging the kernels. Look for features like adjustable airflow, vibration mechanisms, and sieving systems that optimize shell removal while minimizing kernel loss.

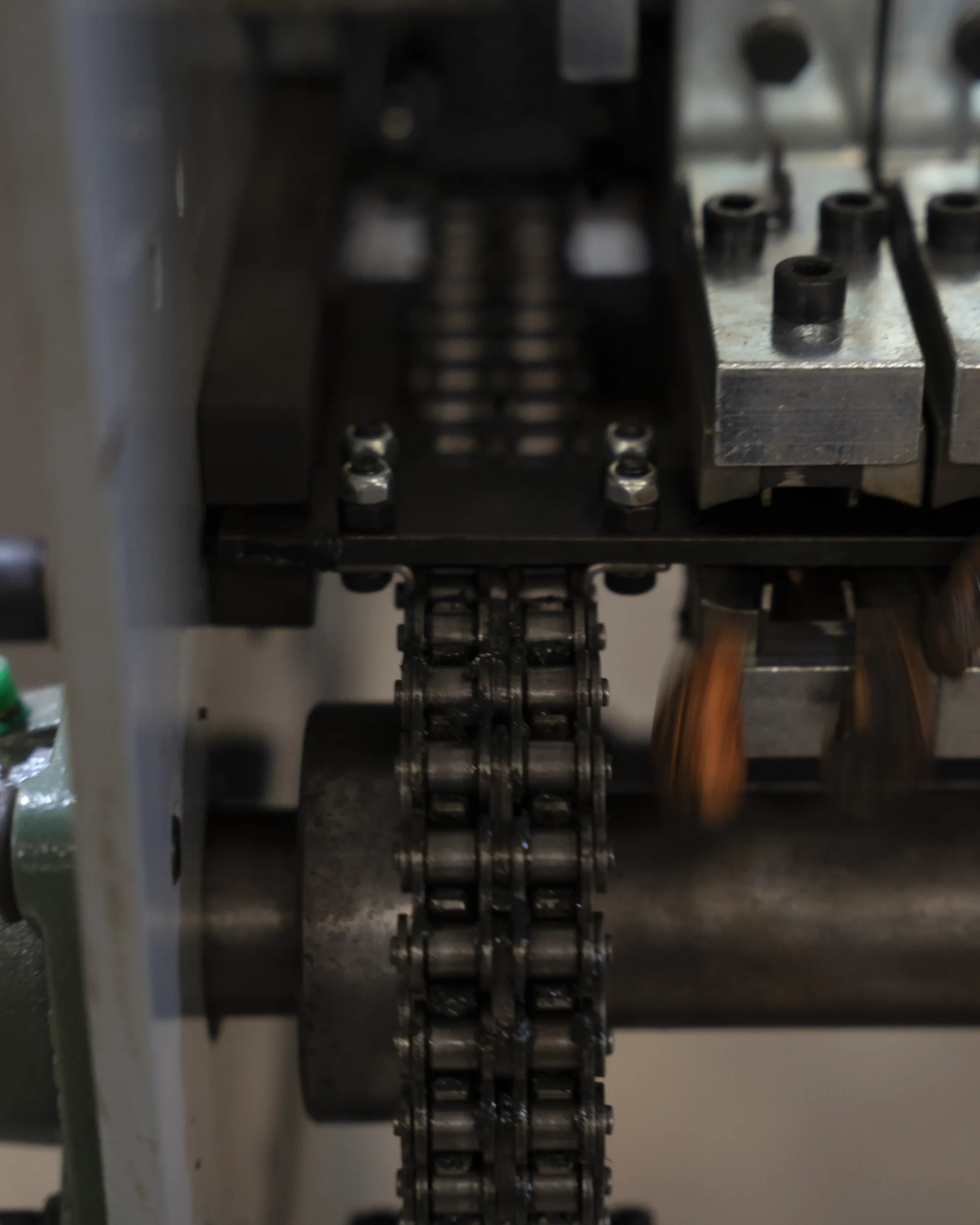

3. Maintenance and Durability

Consider the quality of materials used in its construction and the reputation of the manufacturer. Look for machines that are easy to clean and have accessible parts for routine maintenance. Additionally, consider the availability of spare parts and after-sales support to minimize downtime.

4. Cost and Budget

While cost is an important factor, prioritize value for money over the cheapest option. Consider the long-term benefits, such as increased productivity, reduced labor costs, and improved quality, when assessing the machine’s overall cost-effectiveness.

5. Safety Features

Ensure the cashew shelling machine you choose has adequate safety features to protect operators from potential hazards. Look for features such as emergency stop buttons, safety interlocks, and protective enclosures. Safety should be a top priority to prevent accidents and maintain a secure working environment.

Types of Cashew Shelling Machines

There are different types of cashew shelling machines available on the market, each with its own advantages and suitability for specific business requirements. Familiarize yourself with these types to make an informed decision:

1. Manual Shelling Machines

Manual cashew shelling machines are suitable for small-scale operations or businesses with limited budgets. They are operated by hand and require manual labor to remove the cashew shells. While they are affordable, manual machines have lower capacity and are less efficient compared to automated options.

2. Semi-Automatic Shelling Machines

Semi-automatic cashew shelling machines combine manual labor with automated processes. They offer a balance between affordability and improved productivity.

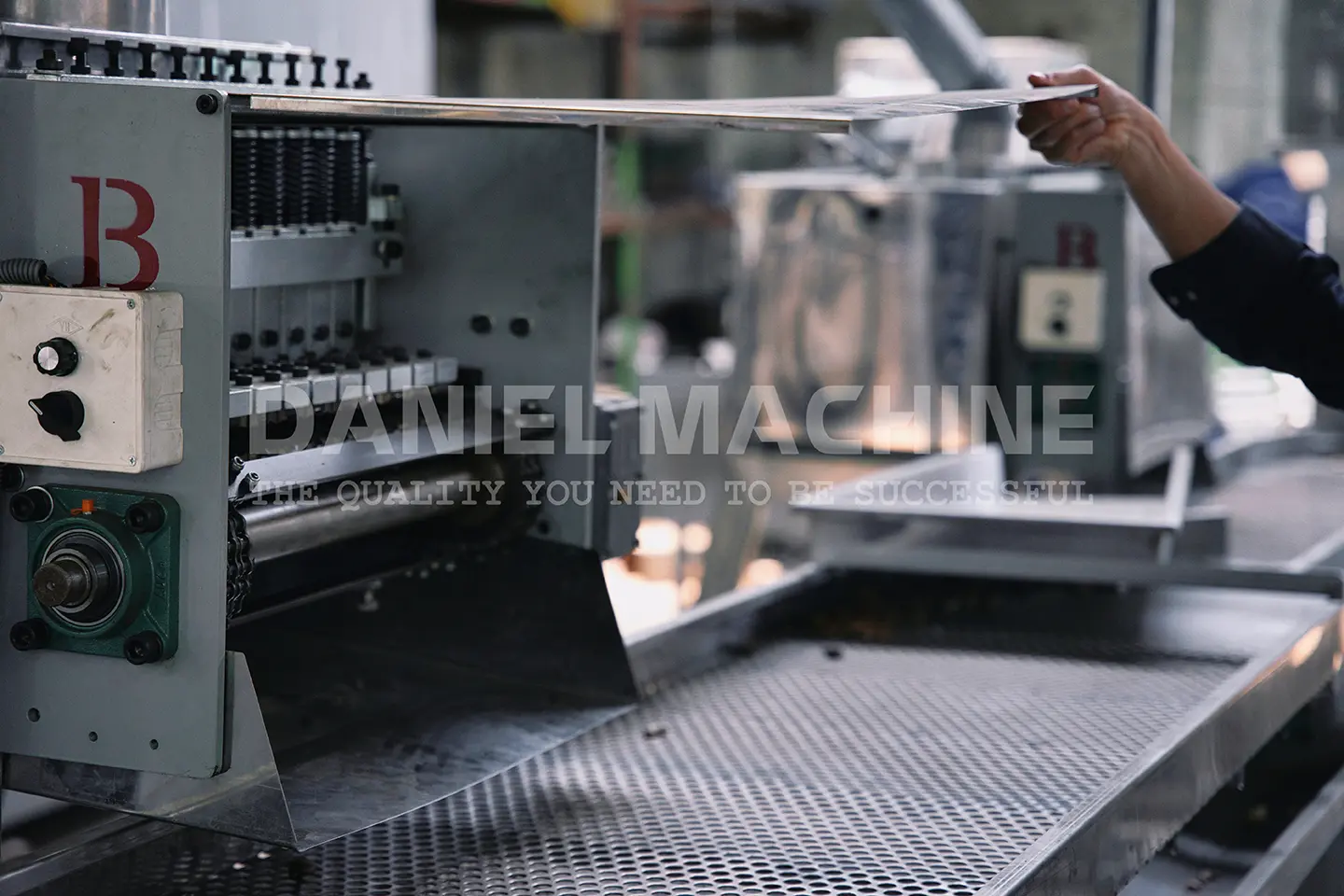

3. Fully automatic shelling machines

Fully automatic cashew shelling machines are the most advanced and efficient option available. They require minimal manual intervention and can handle large volumes of cashews with high precision and speed. These machines are suitable for large-scale cashew processing businesses with high production demands.

Understanding the Cashew Shelling Process

Before choosing a cashew shelling machine, it is essential to understand the cashew shelling process. The machine should align with your specific processing requirements and be capable of handling the size, shape, and moisture content of the cashews you process. Consider factors such as the initial grading of cashews, steaming requirements, and the need for additional drying before selecting a suitable machine.

Evaluating Different Cashew Shelling Machine Suppliers

When selecting a cashew shelling machine, it is important to evaluate different suppliers and manufacturers to ensure you choose a reliable and reputable one. Consider the following factors during the evaluation process:

1. Reputation and experience

Look for suppliers with a solid reputation and extensive experience in manufacturing cashew processing equipment. A supplier with a proven track record is more likely to provide high-quality machines and reliable customer service.

2. Customer reviews and testimonials

Read customer reviews and testimonials to gain insights into the experiences of others who have purchased cashew shelling machines from the suppliers you are considering. Positive feedback and satisfied customers are indicators of a reputable supplier.

3. After-Sales Support and Warranty

Check if the supplier offers comprehensive after-sales support, including training, technical assistance, and troubleshooting. Additionally, inquire about the warranty provided with the machine to ensure you are covered in case of any defects or issues.

Tips for Choosing the Right One

To choose the most suitable machine for your business, follow these tips:

1. Assessing Your Business Needs

Evaluate your business requirements in terms of cashew processing volume, future growth projections, and budget constraints. This assessment will help you determine the capacity and type of cashew shelling machine that best suit your needs.

2. Comparing Features and Specifications

Compare the features and specifications of different cashew shelling machines to find the one that meets your specific requirements. Pay attention to factors such as capacity, efficiency, shell separation systems, maintenance needs, and safety features.

3. Requesting Demos and Trials

Whenever possible, request demos or trials of the machines you are considering. This hands-on experience will allow you to assess the performance, ease of use, and suitability of the machine for your business operations.

4. Seeking expert advice

Consult industry experts, cashew processing consultants, or other business owners who have experience in cashew processing. Their insights and recommendations can help you make an informed decision when choosing a cashew shelling machine.

Conclusion

Selecting the right cashew shelling machine is crucial for the success of your cashew processing business. Consider factors such as capacity, efficiency, shell separation system, maintenance, safety features, and budget when making your decision. Evaluate different suppliers, read customer reviews, and seek expert advice to ensure you choose a reliable and high-quality machine that aligns with your business needs. With the right cashew shelling machine, you can streamline your cashew processing operations, increase productivity, and achieve better profitability.

FAQs

How much does a cashew shelling machine cost?

Prices can range from a few thousand dollars to tens of thousands of dollars.

Can a cashew shelling machine handle different cashew sizes?

Yes, cashew shelling machines are designed to handle various cashew sizes. However, it is important to choose a machine that can be adjusted or customized to accommodate the specific size range of cashews you process.

Are there any safety precautions when operating a cashew shelling machine?

Operators should wear protective gear, such as gloves and goggles, to prevent injuries. Additionally, the machine should be equipped with safety features like emergency stop buttons and protective enclosures to ensure a safe working environment.

What is the maintenance required for a cashew shelling machine?

Cashew shelling machines require regular maintenance to ensure optimal performance. This includes routine cleaning, lubrication of moving parts, and periodic inspection for any wear or damage. The manufacturer’s guidelines and recommendations should be followed for proper maintenance.

Are there any alternatives to cashew shelling machines?

While cashew shelling machines are the most efficient and preferred option for large-scale cashew processing, there are alternative methods available. These include manual shelling, using specialized hand tools, or outsourcing the shelling process to third-party service providers. However, these alternatives are usually more labor-intensive and time-consuming and may result in lower quality and productivity.