In today’s competitive market, cashew processing businesses are constantly looking for ways to improve efficiency, reduce costs, and scale their operations. Small cashew shelling machines are an ideal solution for growing businesses that want to optimize their production process without investing in large-scale industrial equipment. These machines offer flexibility, increased output, and cost-effective solutions to meet the needs of small to medium-sized cashew processors.

As your business expands, manually shelling cashews becomes a time-consuming and labor-intensive process. While larger companies may invest in high-end industrial shellers, small cashew shelling machines provide an affordable alternative that still delivers efficiency. These machines are designed for businesses that have a moderate production scale but need to speed up the shelling process without sacrificing quality.

Key Benefits of Small Cashew Shelling Machines:

- Cost-Effective: Ideal for businesses that need to increase output without making a huge upfront investment.

- Compact Size: Perfect for businesses with limited space or those looking to operate in smaller facilities.

- Ease of Use: Most machines come with user-friendly controls, minimizing the need for specialized training.

- High Efficiency: Even smaller machines can significantly increase production capacity compared to manual shelling.

Features to Look for in a Small Cashew Shelling Machine

When choosing a cashew shelling machine for your growing business, it’s important to consider certain features that will contribute to efficiency and ease of use. Here are some of the top features to look for:

Adjustable Shelling Settings: Different batches of cashews may vary in size, and adjustable settings allow you to accommodate these differences. Machines with adjustable shelling pressure and size specifications can handle a wider variety of cashew grades.

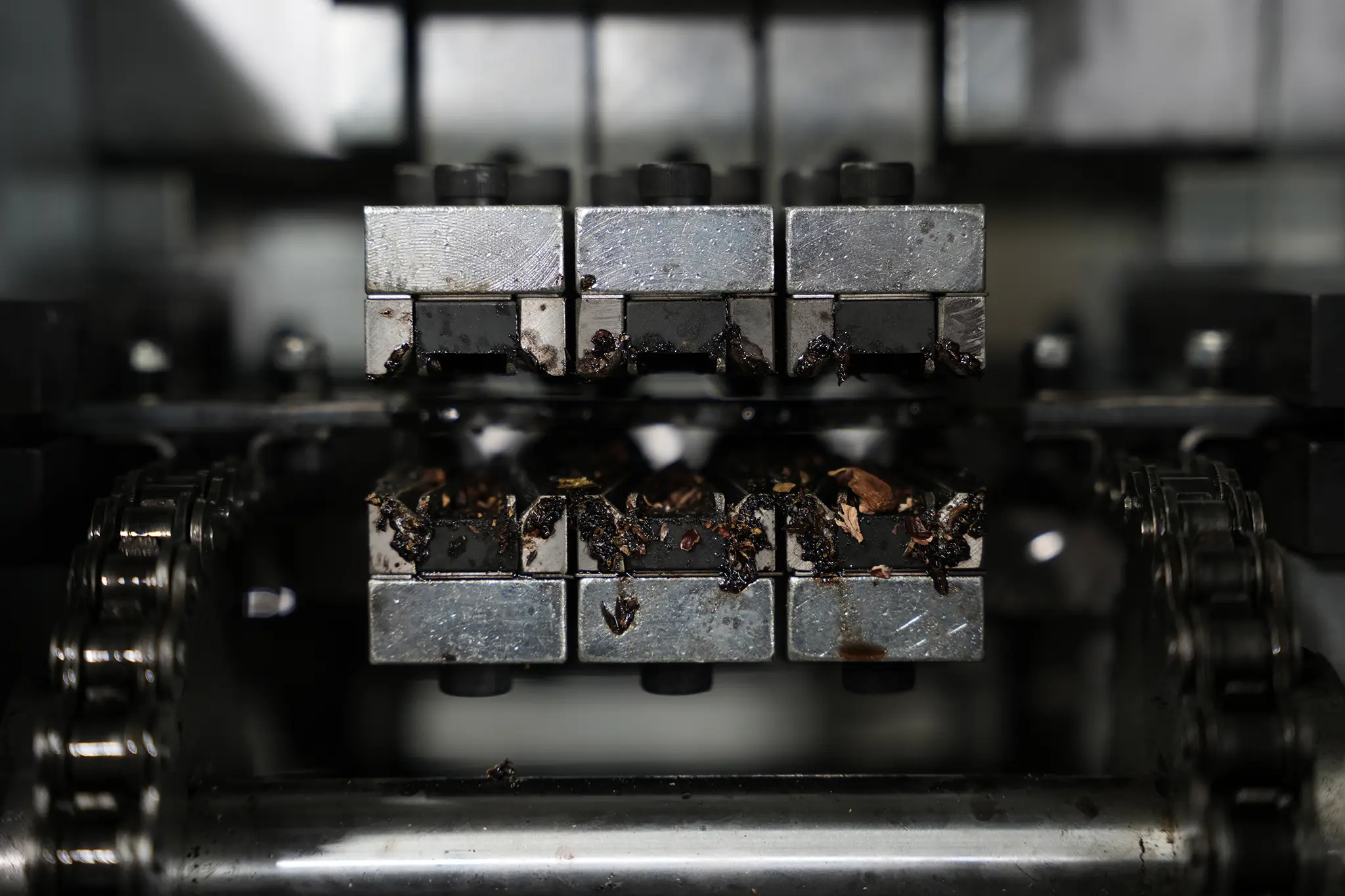

Durability and Build Quality: Since shelling machines will be in constant use, look for models built from durable materials like stainless steel to ensure they withstand wear and tear over time.

Energy Efficiency: Small businesses often need to keep operational costs low. Look for machines that offer energy-efficient motors to save on electricity while maintaining output.

Safety Features: Machines with built-in safety guards and automatic shut-off features help protect workers from accidents and extend the life of the equipment.

How Small Cashew Shelling Machines Increase Production Efficiency

For a growing business, increasing production efficiency is key to scaling without incurring prohibitive costs. Small cashew shelling machines are designed to streamline the shelling process, automating repetitive tasks and reducing the need for manual labor. This not only speeds up production but also ensures a more consistent product quality, as machines are less prone to human error.

Many modern machines also feature automation capabilities that allow for continuous shelling, which drastically reduces downtime between batches. By incorporating these machines into your production line, you can increase throughput without needing to significantly expand your workforce.

Types of Small Cashew Shelling Machines for Your Business

There are several types of cashew shelling machines available on the market, each with its own set of benefits and functionalities. Understanding the different types will help you choose the best one for your business.

Manual Cashew Shelling Machines: These are small, hand-operated machines that are best suited for micro-businesses or those just starting out. They are cost-effective but require manual labor to operate, making them less efficient for businesses that need to process large volumes.

Semi-Automatic Cashew Shelling Machines: These machines require minimal manual intervention and can process a moderate number of cashews per hour. They are ideal for businesses looking to scale up from manual shelling operations without fully automating their production line.

Fully Automatic Cashew Shelling Machines: Fully automated machines are the most efficient, capable of processing large quantities of cashews with minimal human oversight. They are a good investment for businesses that plan to rapidly scale in the near future but might be overkill for smaller businesses with limited production needs.

How to Choose the Right Small Cashew Shelling Machine for Your Business

Selecting the right cashew shelling machine for your business depends on several factors, including your production scale, budget, and future growth plans. Start by assessing your current production needs and anticipated growth. If you’re a smaller operation with limited space, a semi-automatic or manual machine might be the best choice. For businesses planning to scale rapidly, investing in a fully automated machine could be the most cost-effective solution in the long run.

Always consider the balance between cost and functionality. While it might be tempting to invest in the most advanced machine available, it’s important to ensure that the machine aligns with your business’s production requirements and budget constraints.

Conclusion

Small cashew shelling machines provide growing businesses with a powerful tool to increase productivity, reduce labor costs, and maintain high-quality output. Whether you opt for a manual, semi-automatic, or fully automated machine, investing in the right equipment can help your business scale efficiently while keeping operational costs manageable. By selecting the best machine for your needs and maintaining it properly, your cashew processing business will be well-positioned for continued growth.