Description

The Importance of Cashew Processing

Cashew nuts are a significant agricultural product for many tropical countries, providing substantial economic benefits. Proper processing is crucial for maintaining the quality of the nuts and ensuring they are safe for consumption. The primary objectives of cashew processing include:

- Removing the toxic shell oil (Anacardic acid): This is crucial as the oil can cause skin irritation and other health issues.

- Ensuring the nut’s quality: Proper processing helps in retaining the nut’s nutritional value and flavor.

- Maximizing yield: Efficient processing ensures that a maximum number of nuts are retrieved intact.

- Maintaining hygiene: Ensuring that the nuts are processed in a clean environment to meet food safety standards.

Overview of the Cashew Processing Machine Line

A typical cashew processing machine line comprises several stages, each with specialized machinery designed to handle specific tasks. These stages include:

- Roasting or Steaming

- Shelling

- Drying

- Peeling

- Grading

- Packaging

Each stage is critical and involves sophisticated equipment that works in harmony to ensure seamless processing. Let’s explore each stage in detail.

1. Roasting or Steaming

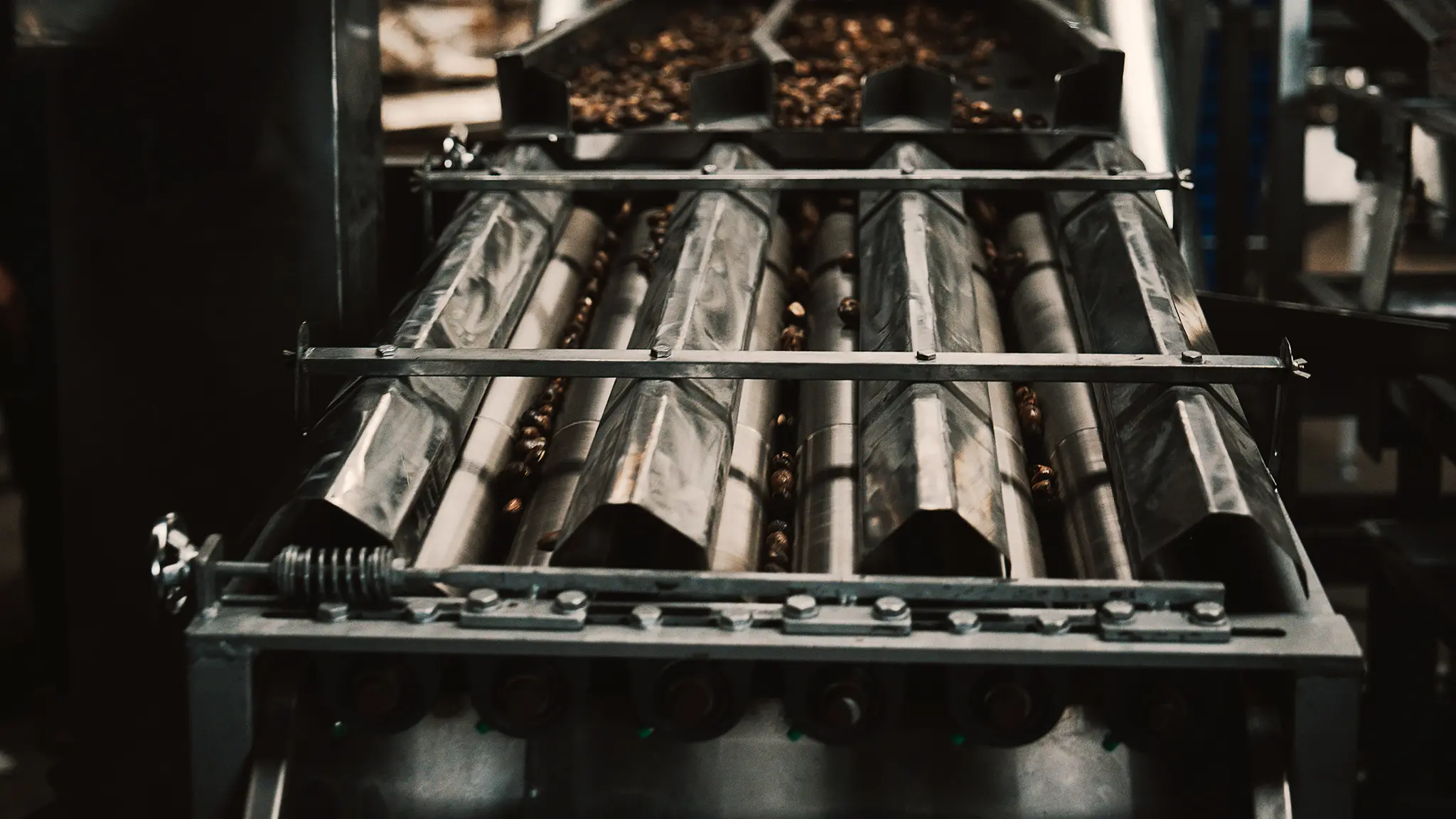

The first step in cashew processing is to prepare the nuts for shelling. This is typically done through roasting or steaming, which helps to loosen the shell and makes it easier to remove.

- Roasting Machines: These machines use dry heat to roast the cashew nuts. The roasting temperature and duration are carefully controlled to ensure that the nuts are evenly roasted without being burnt. This process not only loosens the shell but also enhances the flavor of the nuts.

- Steaming Machines: Alternatively, steaming machines use moist heat to soften the shells. This method is preferred by some processors as it is more gentle on the nuts and can result in a higher yield of whole kernels.

Both methods are effective, and the choice between roasting and steaming often depends on the specific preferences and requirements of the processing facility.

2. Shelling

Shelling is the process of removing the hard outer shell of the cashew nut. This is a critical step as it needs to be done carefully to avoid damaging the delicate kernel inside.

- Manual Shelling Machines: Traditional methods involve manual shelling, which is labor-intensive and time-consuming. However, modern manual shelling machines have been developed to improve efficiency while retaining the precision of manual handling.

- Automatic Shelling Machines: These machines have revolutionized the shelling process. They are equipped with advanced sensors and cutting mechanisms that can accurately and efficiently remove the shells without damaging the kernels. Automatic shelling machines can process large volumes of cashew nuts in a short time, significantly reducing labor costs and increasing productivity.

3. Drying

After shelling, the cashew kernels need to be dried to reduce their moisture content. Proper drying is essential to prevent mold growth and ensure the nuts have a long shelf life.

- Drying Ovens: These are commonly used for drying cashew kernels. The ovens are designed to circulate hot air evenly, ensuring that the kernels are dried uniformly. The temperature and drying time are carefully controlled to achieve the desired moisture content without affecting the quality of the nuts.

- Solar Dryers: In some regions, solar dryers are used as an eco-friendly and cost-effective alternative to drying ovens. These dryers use solar energy to heat the air, which is then circulated through the drying chamber to dry the kernels.

4. Peeling

Once the kernels are dried, the next step is to remove the thin, papery skin that covers the nuts. This process is known as peeling.

- Manual Peeling Machines: Similar to shelling, traditional peeling methods involve manual labor. Manual peeling machines can improve efficiency while maintaining the precision required to avoid damaging the kernels.

- Automatic Peeling Machines: These machines use a combination of mechanical and pneumatic systems to gently peel the skin from the kernels. Automatic peeling machines are designed to handle large volumes of nuts quickly and efficiently, ensuring a high yield of whole kernels.

5. Grading

Grading is the process of sorting the cashew kernels based on their size, color, and quality. This is an important step as it determines the final market value of the nuts.

- Manual Grading: In traditional processing facilities, grading is often done manually by skilled workers who visually inspect the kernels and sort them accordingly.

- Automatic Grading Machines: Modern processing lines use advanced grading machines equipped with optical sensors and imaging technology. These machines can accurately and efficiently sort the kernels based on predefined criteria, ensuring consistent quality and reducing the risk of human error.

6. Packaging

The final step in the cashew processing line is packaging. Proper packaging is essential to protect the nuts from contamination and damage during storage and transportation.

- Vacuum Packing Machines: These machines are used to pack the cashew kernels in airtight bags, which helps to extend their shelf life by preventing exposure to air and moisture.

- Sealing Machines: Sealing machines are used to seal the bags or containers to ensure they are airtight and secure.

- Labeling Machines: These machines are used to label the packages with important information such as the product name, batch number, and expiration date.

Benefits of Cashew Processing Machine Lines

The introduction of cashew processing machine lines has brought numerous benefits to the industry:

- Increased Efficiency: Automated machines can process large volumes of cashew nuts quickly and accurately, significantly increasing productivity.

- Reduced Labor Costs: Automation reduces the need for manual labor, which can help to lower labor costs and increase profitability.

- Improved Quality: Advanced machines are designed to handle the nuts gently and precisely, ensuring a high yield of whole kernels and consistent quality.

- Enhanced Food Safety: Automated processing reduces the risk of contamination and ensures that the nuts are processed in a clean and hygienic environment.

- Greater Flexibility: Modern machines are often designed to be easily adjustable, allowing processors to handle different sizes and varieties of cashew nuts with minimal downtime.

- Sustainability: Some advanced machines are designed to be energy-efficient and environmentally friendly, helping processors to reduce their carbon footprint.

Challenges and Considerations

While cashew processing machine lines offer numerous benefits, there are also challenges and considerations to keep in mind:

- Initial Investment: The cost of purchasing and installing a cashew processing machine line can be significant. However, the long-term benefits often outweigh the initial investment.

- Maintenance and Repairs: Regular maintenance is essential to keep the machines in good working condition. Processors need to be prepared for potential downtime and repair costs.

- Training: Operators need to be trained to use and maintain the machines effectively. This requires investment in training programs and ongoing support.

- Adaptability: The processing line needs to be adaptable to handle different sizes and varieties of cashew nuts. This requires careful selection of machinery and equipment.

- Quality Control: Despite the automation, quality control measures need to be in place to ensure the nuts meet the required standards. This includes regular inspections and testing.

Future Trends in Cashew Processing

The cashew processing industry continues to evolve, with ongoing advancements in technology and equipment. Some of the future trends to watch out for include:

- Smart Machines: The integration of IoT (Internet of Things) technology in processing machines can enable real-time monitoring and control, improving efficiency and reducing downtime.

- Robotics: The use of robotics in cashew processing can further enhance precision and speed, particularly in tasks such as sorting and packaging.

- Sustainable Practices: There is a growing focus on sustainability in the food processing industry. Future cashew processing machines are likely to be more energy-efficient and environmentally friendly.

- Advanced Quality Control: The use of AI (Artificial Intelligence) and machine learning in quality control can help to detect defects and ensure consistent quality more effectively.

- Customization: As consumer preferences continue to evolve, there is likely to be a greater demand for customized cashew products. Processing lines may need to be more flexible and adaptable to meet these changing demands.

Conclusion

The cashew processing machine line represents a significant advancement in the cashew industry, transforming traditional methods into a more efficient, cost-effective, and high-quality process. By understanding the various stages of the processing line and the benefits they bring, processors can make informed decisions to enhance their operations and meet the growing demand for cashew nuts. As technology continues to evolve, the future of cashew processing looks promising, with new innovations set to further improve efficiency, quality, and sustainability in the industry.

There are no reviews yet.