The cashew nut industry has seen significant advancements in recent years, and one such development is the automatic cashew scooping machine. This innovative equipment has transformed the traditional manual processes, making it easier, faster, and more efficient to extract cashew kernels from their shells. If you’re looking to improve productivity in your cashew processing operations, understanding the different types of cashew scooping machines is essential.

Before diving into the specifics of the automatic cashew scooping machine, it’s worth exploring the different types of cashew scooping machines available on the market. These machines vary in design, automation level, and functionality, catering to different scales of cashew processing.

Manual Cashew Scooping Machine:

These are traditional machines operated manually. They require physical effort and are suitable for small-scale operations. While they are cost-effective, their efficiency is limited, making them less ideal for large-scale processing.

Semi-Automatic Cashew Scooping Machine:

Semi-automatic machines bridge the gap between manual and fully automatic systems. They require some manual intervention but offer better speed and consistency than manual machines. They are often used by medium-sized processing units.

Automatic Cashew Scooping Machine:

Automatic machines represent the pinnacle of cashew processing technology. They operate with minimal human intervention, delivering high throughput and consistent quality. These machines are ideal for large-scale processing facilities where efficiency and speed are paramount.

What is an Automatic Cashew Scooping Machine?

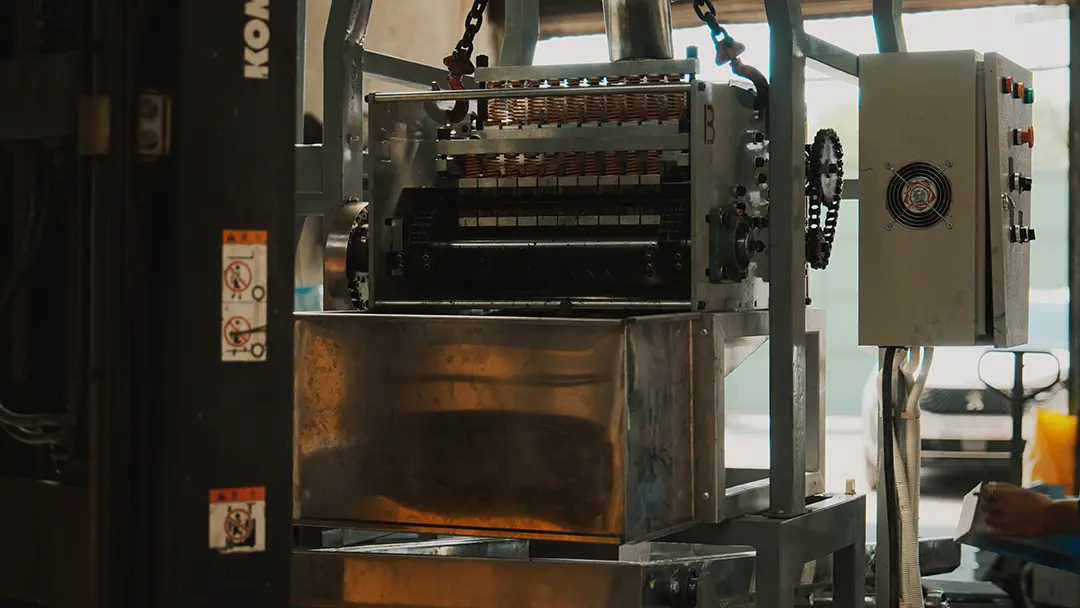

An automatic cashew scooping machine is a specialized piece of equipment designed to efficiently remove cashew kernels from their shells. It automates the scooping process, significantly reducing the labor required and minimizing kernel damage. The machine uses advanced mechanisms to separate the kernel from the shell with precision.

Benefits of Using an Automatic Cashew Scooping Machine

The adoption of automatic cashew scooping machines offers numerous advantages for cashew processors:

Increased Efficiency: Automatic machines can process a large volume of cashews in a fraction of the time it takes using manual methods. This boost in productivity can significantly reduce operational costs.

Consistent Quality: The precision of automatic machines ensures that the kernels are scooped out with minimal breakage, preserving the quality of the cashew nuts.

Reduced Labor Costs: By automating the scooping process, businesses can cut down on labor expenses. The machine can handle tasks that would otherwise require a team of workers.

Improved Safety: Manual scooping can be hazardous, especially when dealing with sharp shells. Automatic machines eliminate this risk, providing a safer working environment for employees.

How Does an Automatic Cashew Scooping Machine Work?

Automatic cashew scooping machines are designed with intricate components that allow for efficient processing. Here’s a breakdown of the typical process:

Shell Detection: The machine identifies the position and orientation of each cashew nut, ensuring that it is placed correctly for scooping.

Scooping Mechanism: Using a set of specially designed blades or scooping tools, the machine delicately removes the kernel from the shell without damaging it.

Kernel Separation: The extracted kernels are separated from the shells, with the machine sorting them based on size and quality.

Collection and Packaging: The kernels are then collected in containers, ready for further processing or packaging.

Choosing the Right Automatic Cashew Scooping Machine

When selecting an automatic cashew scooping machine, consider the following factors:

Processing Capacity:

Determine the volume of cashews you need to process daily. Machines with higher capacity can handle larger volumes but may come at a higher price.

Quality of Scooping:

Look for machines that offer precision scooping to minimize kernel damage. High-quality machines will have advanced mechanisms that ensure clean scooping.

Ease of Maintenance:

Choose a machine that is easy to clean and maintain. Regular maintenance is crucial to prevent downtime and prolong the life of the equipment.

Brand and Warranty:

Opt for reputable brands that offer good customer support and a reliable warranty. This ensures that you have access to parts and service when needed.

Conclusion

The efficiency of an automatic cashew scooping machine cannot be overstated. Whether you are a small business looking to scale up or a large processor aiming to enhance productivity, investing in the right machine can revolutionize your operations. By automating the scooping process, you not only increase throughput but also improve the quality and consistency of your product. Explore your options and choose a machine that aligns with your processing needs to stay ahead in the competitive cashew industry.