Cashews have carved their place as one of the most sought-after nuts globally, prized for their rich flavor and nutritional value. Their popularity has propelled the cashew market into a lucrative space, attracting businesses seeking opportunities in this industry.

However, despite the profitability, cashew processing has long faced a bottleneck – the laborious and intricate task of shelling cashews manually. This process not only consumes time but also presents challenges in maintaining quality and consistency, hindering businesses from maximizing their potential.

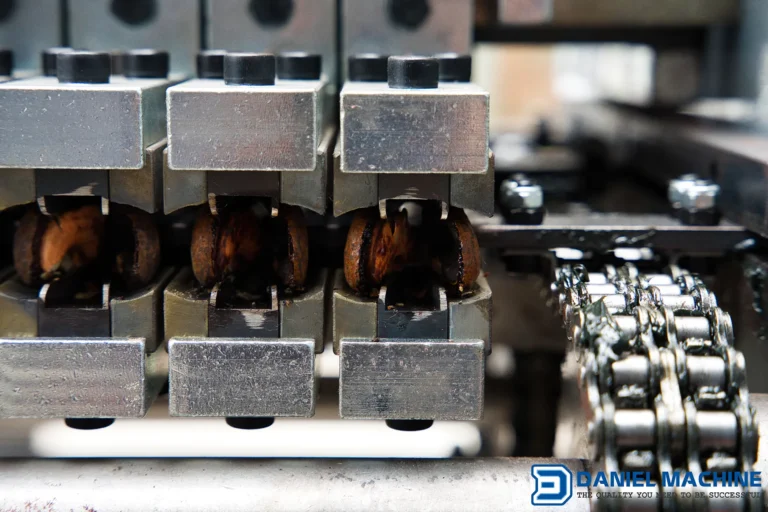

Enter the Cashew Shelling Machine: A Game-Changer

Thankfully, technology comes to the rescue with cashew shelling machines. These innovative machines have revolutionized the cashew processing industry, offering multifaceted advantages that redefine efficiency, quality, and profitability for businesses involved in cashew processing. Let’s explore the diverse benefits these machines bring to the table.

Unveiling the Benefits of Cashew Shelling Machines

Enhanced Efficiency and Productivity

Say Goodbye to Manual Labor

Traditional manual shelling methods are labor-intensive, demanding countless hours and manpower. Cashew shelling machines automate this process, significantly reducing reliance on manual labor. These machines can shell a large volume of cashews efficiently, exponentially increasing productivity.

Increased Cashew Output

The efficiency of cashew shelling machines translates into a remarkable increase in cashew output. Their precision and speed allow businesses to meet higher demands, catering to market needs without compromising on quality.

Reduced Production Time

Moreover, the rapid shelling process considerably cuts down production time. What used to take days or weeks can now be accomplished in a fraction of the time, empowering businesses to meet deadlines and capitalize on market opportunities swiftly.

Improved Cashew Quality

Minimized Breakage and Damage

Manual shelling often leads to breakage and damage to cashew kernels, affecting their quality and market value. Cashew shelling machines, with their precision and gentle handling, minimize such damage, ensuring a higher yield of intact, premium-quality kernels.

Enhanced Hygiene and Safety

Another significant advantage is the improved hygiene and safety standards brought by these machines. They operate in enclosed environments, reducing contamination risks, and adhere to safety protocols, ensuring a hygienic processing environment, which is crucial for maintaining high-quality standards.

Consistent Yield of High-Quality Cashews

Consistency is key in the cashew industry. Shelling machines ensure a uniform yield of high-quality cashews, meeting market expectations consistently, and fostering consumer trust and loyalty.

Reduced Operational Costs

Lower Labor Expenses

One of the most noticeable cost reductions comes from decreased labor expenses. The reduced dependency on manual labor not only streamlines operations but also trims the associated costs, contributing significantly to overall savings.

Reduced Energy Consumption

Additionally, these machines are designed for energy efficiency, consuming significantly less power compared to traditional methods. This reduction in energy consumption not only saves costs but also aligns with sustainable practices, reducing the ecological footprint of cashew processing operations.

Increased Profitability

Cumulatively, the efficiency improvements, cost reductions, and enhanced output translate into increased profitability for businesses investing in cashew shelling machines. The initial investment proves to be a strategic move that pays off in the long run, boosting overall profitability.

Enhanced Business Scalability

Adapt to Growing Demands

In a dynamic market, adaptability is crucial. Cashew shelling machines equip businesses to scale operations swiftly, accommodating increased demands without compromising quality or incurring substantial operational changes.

Expand Your Market Reach

The capability to meet higher production demands enables businesses to explore new markets and expand their reach. With a reliable supply of high-quality cashews, they can confidently tap into diverse consumer segments, fostering growth and diversification.

Secure Your Position in the Cashew Industry

By embracing cashew shelling machines, businesses solidify their position in the cashew industry. Staying ahead of competitors, meeting market demands, and consistently delivering quality products are key factors in establishing a strong foothold in the industry.

Choosing the Right Cashew Shelling Machine for Your Business

Factors to Consider

When selecting a cashew shelling machine, several crucial factors need consideration to ensure it aligns with the specific needs and goals of the business.

Capacity and Processing Speed

The capacity and processing speed of the machine should match the anticipated workload. Assessing the daily processing requirements helps in determining the ideal machine capacity.

Cashew Variety and Size

Different cashew varieties and sizes may require specific machine specifications. Ensuring compatibility between the machine and the cashew variety being processed is vital for optimal performance.

Power Consumption and Energy Efficiency

Evaluate the energy efficiency ratings and power consumption of the machine to balance operational costs and environmental impact.

Budget and Investment Considerations

The initial investment, maintenance costs, and long-term returns should be factored in when deciding on the most suitable machine within budget constraints.

Popular Cashew Shelling Machine Options

There are various types of cashew shelling machines available in the market, each with distinct features and functionalities catering to different business requirements.

Semi-Automatic Cashew Shelling Machines

These machines offer a balance between automation and manual control, allowing businesses to oversee the shelling process while benefitting from automation.

Fully-Automatic Cashew Shelling Machines

Fully automated machines handle the entire shelling process without requiring extensive manual intervention, ensuring high-speed and precise operations.

Specialized Cashew Shelling Machines

Specialized machines cater to specific cashew processing needs, such as those designed for larger capacities or unique processing requirements, offering tailored solutions for diverse business setups.

Optimizing Your Cashew Shelling Operations

Maintenance and Care

Regular Cleaning and Inspection

Proper maintenance involves routine cleaning and inspection to ensure the machine operates at optimal efficiency. Regular checks prevent malfunctions and maintain quality standards.

Proper Storage and Handling

Proper storage of cashews and machine parts, along with appropriate handling practices, prolongs the lifespan of both the cashews and the machine, ensuring consistent quality output.

Timely Replacement of Worn-Out Parts

Identifying and replacing worn-out parts promptly is crucial to prevent disruptions in operations and maintain the machine’s efficiency.

Training and Skill Development

Providing Training for Operators

Proper training equips operators with the necessary skills to operate the machines efficiently, reducing the risk of errors and ensuring smooth operations.

Emphasizing Safety and Hygiene Practices

Training should also emphasize safety protocols and hygiene practices to maintain a safe working environment and high-quality standards.

Encouraging Continuous Learning and Improvement

Encouraging a culture of continuous learning among the team fosters innovation and improvement in operating procedures, enhancing overall efficiency.

Beyond Efficiency: The Broader Impact of Cashew Shelling Machines

Empowering Women and Local Communities

Creating Jobs and Economic Opportunities

Cashew processing, especially with the aid of shelling machines, generates employment opportunities, particularly in regions where cashew farming is prevalent, contributing to economic growth.

Improving Working Conditions and Safety

Shelling machines improve working conditions by minimizing hazardous manual labor, creating a safer and healthier work environment.

Supporting Sustainable Cashew Farming Practices

With increased efficiency, cashew shelling machines indirectly promote sustainable farming practices by fostering better utilization of resources and reducing waste.

Conclusion: Embracing the Future of Cashew Processing

Cashew shelling machines represent a pivotal leap in the cashew processing industry, offering multifaceted advantages that enhance efficiency, quality, and sustainability. Embracing these machines isn’t just about optimizing operations; it’s about revolutionizing the way we approach cashew processing, unlocking new opportunities, and fostering a sustainable future.

FAQ

Are cashew shelling machines suitable for small-scale businesses?

Cashew shelling machines come in various sizes, making them adaptable for small-scale businesses. Assessing specific needs and available options is crucial to determine suitability.

Do cashew shelling machines require specialized maintenance?

Routine maintenance involves regular cleaning, inspection, and occasional part replacements. However, specialized maintenance might be needed based on the machine type and workload.

How do cashew shelling machines contribute to sustainability?

These machines streamline operations, reducing wastage and energy consumption, indirectly promoting sustainable cashew farming practices.

What factors should I prioritize when choosing a cashew shelling machine?

Capacity, processing speed, energy efficiency, compatibility with cashew variety, and budget considerations are key factors to prioritize.