Description

Cashew processing is a meticulous and labor-intensive task, one that calls for specialized equipment to ensure efficiency, precision, and profitability. Whether you’re running a small cashew processing unit or a large operation, having the right machinery can make all the difference. We sell cashew shelling machines that cater to all business sizes, designed to streamline operations and reduce manual labor. In this article, we will delve into everything you need to know about cashew shelling machines, from their benefits to key features to look out for.

Why You Need a Cashew Shelling Machine

If you’re in the cashew industry, you probably know that manually shelling cashews is not only time-consuming but also highly inefficient. Without the right equipment, businesses struggle to meet demand while maintaining quality standards. Enter the cashew shelling machine—a game-changer for businesses looking to scale and maximize output.

Cashew nuts have a hard outer shell that needs to be carefully cracked open without damaging the delicate kernel inside. The cashew shell also contains a toxic oil called “cashew nut shell liquid” (CNSL), making the shelling process even more challenging. By using a cashew shelling machine, these risks are mitigated, allowing you to achieve faster and more precise results with minimal human intervention.

The Advantages of Using Cashew Shelling Machines

One of the primary advantages of investing in a cashew shelling machine is the dramatic increase in production capacity. Machines are capable of processing thousands of cashew nuts per hour, which is significantly higher than manual methods. This increase in productivity translates to higher profitability for your business.

Additionally, cashew shelling machines greatly reduce the risk of injury to workers. Since CNSL is corrosive, manual shelling exposes workers to potential burns and allergic reactions. With an automated shelling machine, workers are protected from such hazards, leading to a safer working environment.

Another benefit of cashew shelling machines is consistency. Machines provide uniform cracking and ensure that the cashew kernels remain intact, reducing the amount of breakage and waste. This consistency improves the quality of your product, which can lead to higher customer satisfaction and better market value.

We Sell Cashew Shelling Machines for Every Business Need

Whether you’re a small business owner or managing a large-scale operation, we have cashew shelling machines that fit every need. Our machines are designed with the latest technology to handle high volumes while ensuring minimal wastage and maximum kernel recovery. We understand that each business has unique requirements, so we offer a variety of models that cater to different production capacities and levels of automation.

Our cashew shelling machines come in both semi-automatic and fully automatic models, allowing you to choose a solution that aligns with your operational goals. For businesses with lower budgets, semi-automatic machines can still greatly enhance productivity compared to manual shelling. On the other hand, fully automated machines offer the highest efficiency, with minimal need for human intervention.

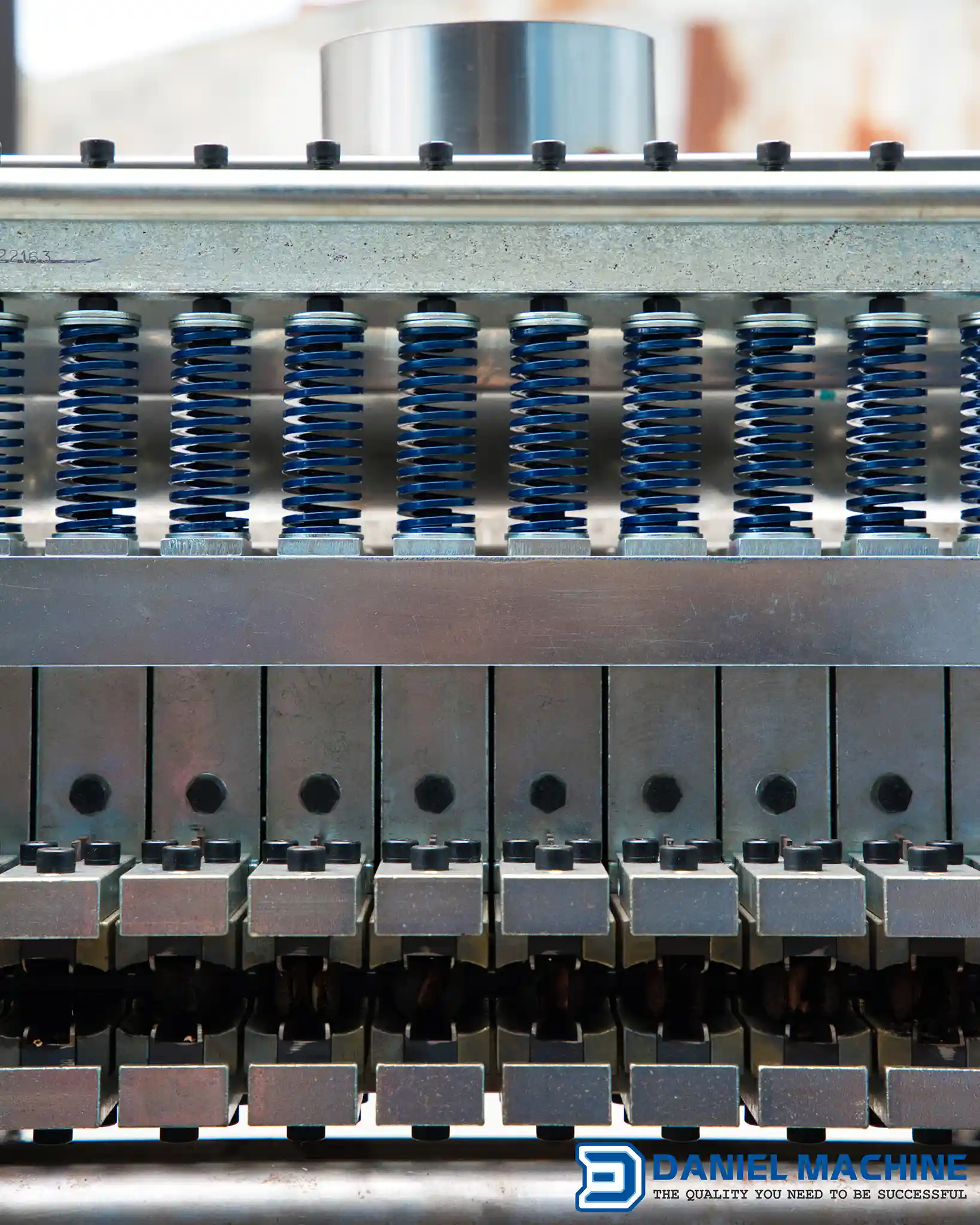

Key Features of Our Cashew Shelling Machines

When investing in a cashew shelling machine, it’s essential to consider the features that will deliver the best value for your business. Here are some of the key features offered by our machines:

- High Efficiency: Our cashew shelling machines are designed to process large volumes of nuts per hour, ensuring that you meet production targets without compromising on quality.

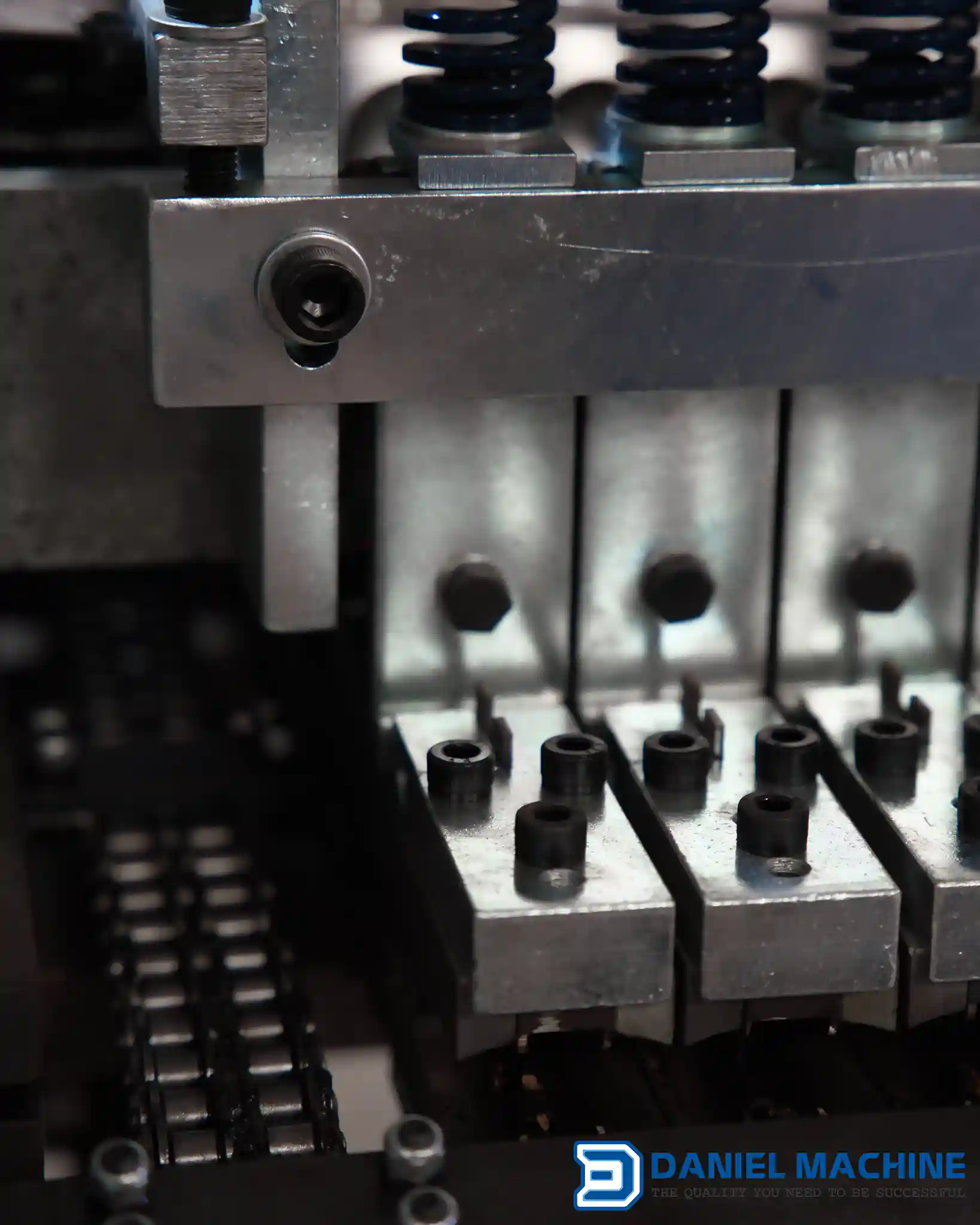

- Kernel Protection: Special care is taken in the design to ensure that the kernels remain intact during the shelling process, minimizing breakage and increasing yield.

- Adjustable Settings: Different cashew varieties and sizes require different shelling techniques. Our machines feature adjustable settings that allow you to fine-tune the operation for optimal results.

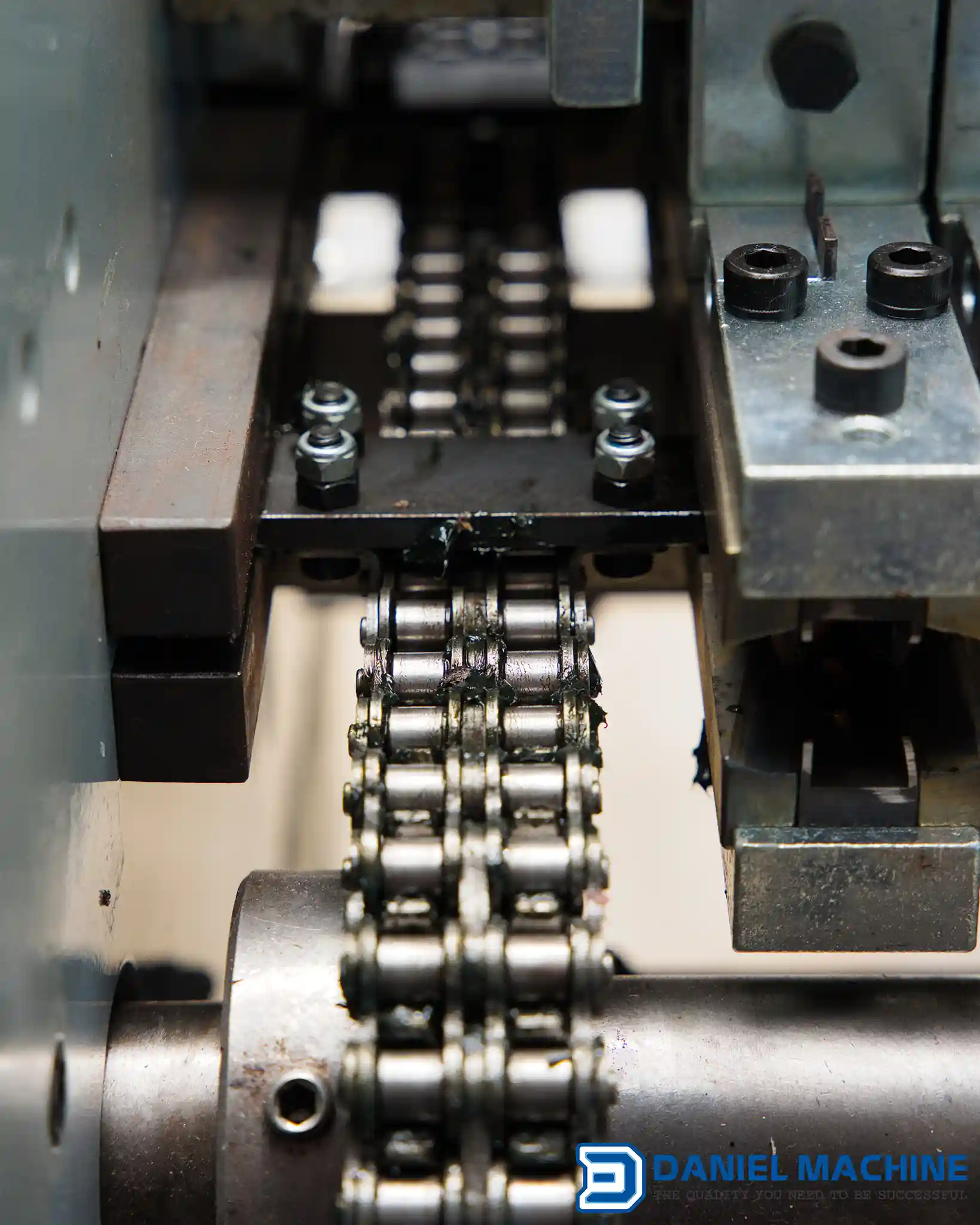

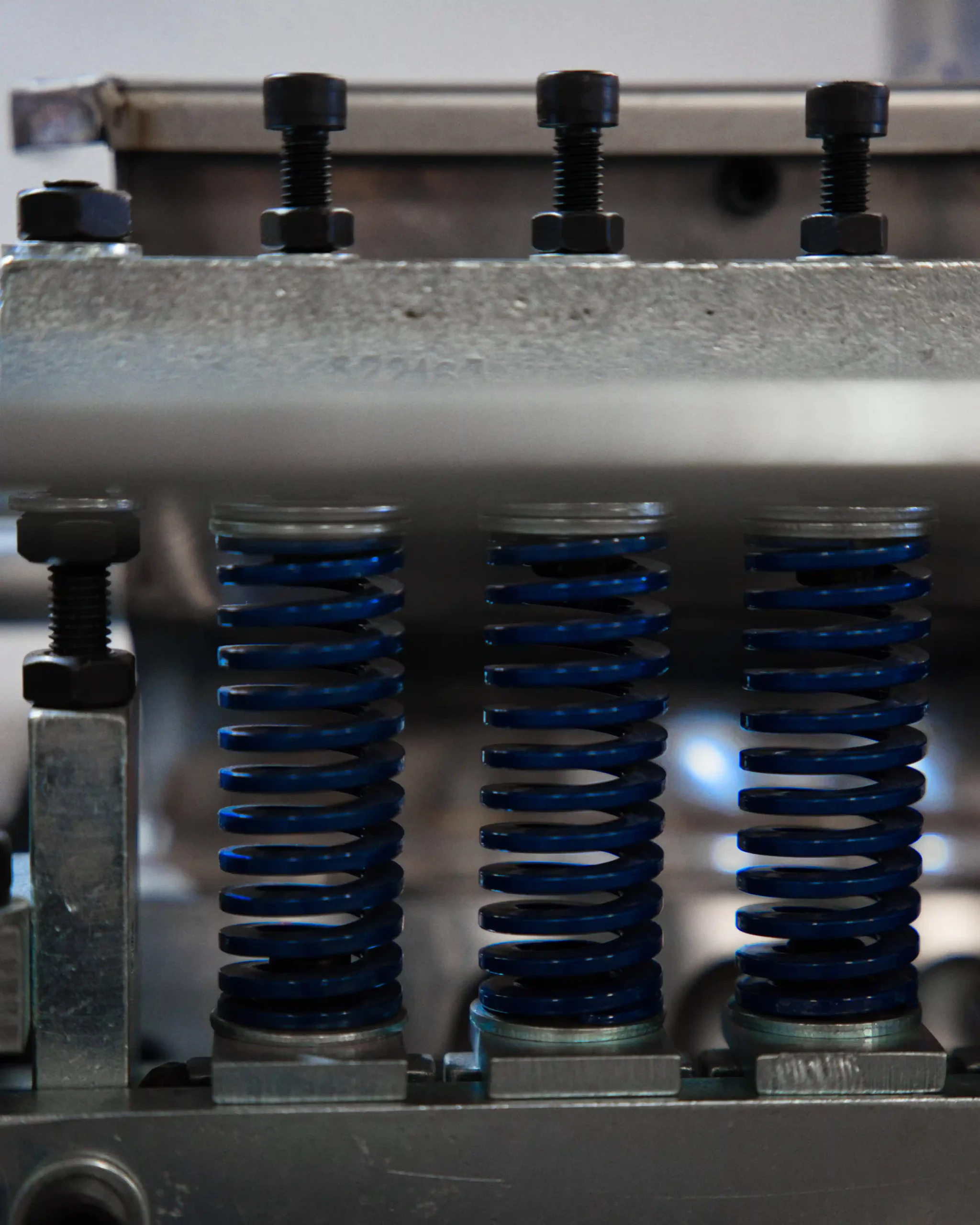

- Durability: Built with high-quality materials, our machines are designed to withstand continuous use over long periods, offering excellent return on investment.

- Ease of Maintenance: Maintenance is crucial for the longevity of any machinery. Our machines are easy to clean and maintain, reducing downtime and ensuring consistent performance.

- Safety Features: To protect your workforce, our machines come equipped with built-in safety mechanisms that prevent accidents during operation.

Choosing the Right Cashew Shelling Machine for Your Operation

Selecting the right cashew shelling machine depends on various factors, such as the scale of your operation, budget, and desired level of automation. For small businesses or startups, a semi-automatic machine might be the most cost-effective option. These machines allow operators to control the shelling process manually while still increasing efficiency over traditional methods.

For larger operations that require high-volume processing, a fully automated machine is the best choice. These machines come with advanced features such as automatic feeding, shelling, and separation of kernels and shells. They also offer higher throughput, making them ideal for businesses looking to scale up production.

Consider the following factors when choosing a cashew shelling machine:

- Production Capacity: Match the machine’s capacity with your business’s processing needs to ensure optimal performance.

- Level of Automation: Determine whether a semi-automatic or fully automatic machine is best suited to your operational workflow.

- Space Requirements: Ensure that you have enough space in your facility to accommodate the machine and any additional equipment needed for operation.

- Budget: While investing in machinery is essential, it’s important to choose a machine that offers the best value for your money.

How Cashew Shelling Machines Improve Profit Margins

Investing in a cashew shelling machine has a direct impact on your bottom line. Not only do these machines increase productivity, but they also reduce labor costs by automating the shelling process. Additionally, since the machine is highly efficient, it reduces the likelihood of damaged kernels, which can otherwise lower the market value of your product.

Machines also save time, allowing you to meet tight deadlines and fulfill larger orders. With increased production and fewer losses, your business can expand its customer base and boost revenue. Moreover, the consistent quality of cashew kernels enhances your reputation in the market, leading to higher customer satisfaction and repeat business.

Environmental Impact of Cashew Shelling Machines

Modern cashew shelling machines are designed with energy efficiency in mind. By using less power while maintaining high productivity, these machines help reduce your business’s carbon footprint. Additionally, the cashew shells themselves can be repurposed for other uses, such as biofuel, minimizing waste and contributing to sustainable practices.

We Sell Cashew Shelling Machines: A Smart Investment for the Future

In a competitive industry like cashew processing, investing in the right equipment is essential for long-term success. We sell cashew shelling machines that not only improve your operational efficiency but also boost profitability by reducing waste and increasing output. Our machines are designed to adapt to the changing needs of your business, ensuring that you stay ahead of the competition.

By automating the shelling process, you can reduce reliance on manual labor and ensure that your production lines run smoothly. Whether you’re just starting or looking to expand your current operation, we have a solution that fits your needs.

FAQs

What is a cashew shelling machine?

A cashew shelling machine is a specialized piece of equipment used to crack open the hard outer shell of cashew nuts while keeping the delicate kernel inside intact.

Why should I invest in a cashew shelling machine?

Investing in a cashew shelling machine increases productivity, reduces labor costs, minimizes kernel breakage, and enhances the overall quality of the cashew nuts you produce.

How does a cashew shelling machine work?

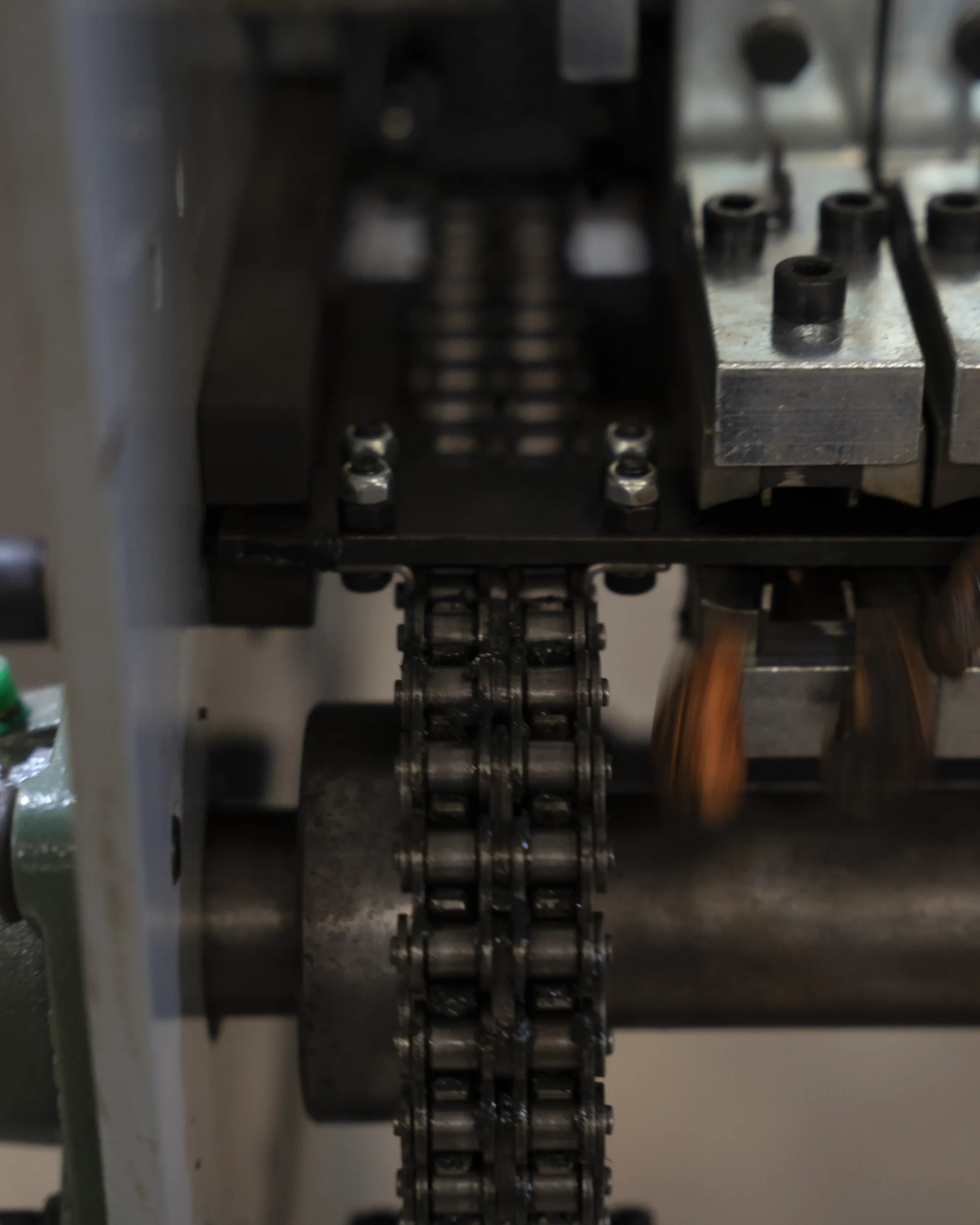

Cashew shelling machines typically use a combination of cutting and compression techniques to crack the outer shell. They are designed to handle large volumes of cashews efficiently, with minimal damage to the kernels.

Can a cashew shelling machine handle different sizes of cashew nuts?

Yes, most cashew shelling machines come with adjustable settings that allow them to process different sizes and varieties of cashew nuts.

What is the maintenance process for a cashew shelling machine?

Regular cleaning and timely maintenance are essential to keep the machine in optimal working condition. Our machines are designed for easy maintenance to reduce downtime and ensure consistent performance.

Are cashew shelling machines safe to use?

Yes, our machines come equipped with various safety features to protect operators from accidents during the shelling process.

There are no reviews yet.