Description

The Efficiency and Precision of a Cashew Cutting Machine: Transforming Cashew Processing

The cashew industry is a vital sector in many tropical countries, contributing significantly to the economy. However, the process of transforming raw cashews into market-ready kernels is labor-intensive and intricate. A crucial part of this process is the cutting of cashew nuts, which has seen remarkable advancements with the advent of the cashew cutting machine.

The Importance of Cashew Cutting

Cashew cutting is essential to separate the edible kernel from the hard shell. This step must be performed with utmost precision to avoid damaging the delicate kernel, which can reduce its market value. Manual cutting, though traditional, is fraught with inconsistencies and potential for injury. The cashew cutting machine addresses these challenges, ensuring uniformity and enhancing safety.

Understanding Cashew Cutting Machines

Evolution of Cashew Cutting Technology

From rudimentary tools to sophisticated machinery, cashew cutting technology has evolved dramatically. Early methods involved manual tools that required significant labor and skill. Modern machines, however, incorporate advanced engineering and automation, streamlining the cutting process and reducing human error.

Key Components of a Cashew Cutting Machine

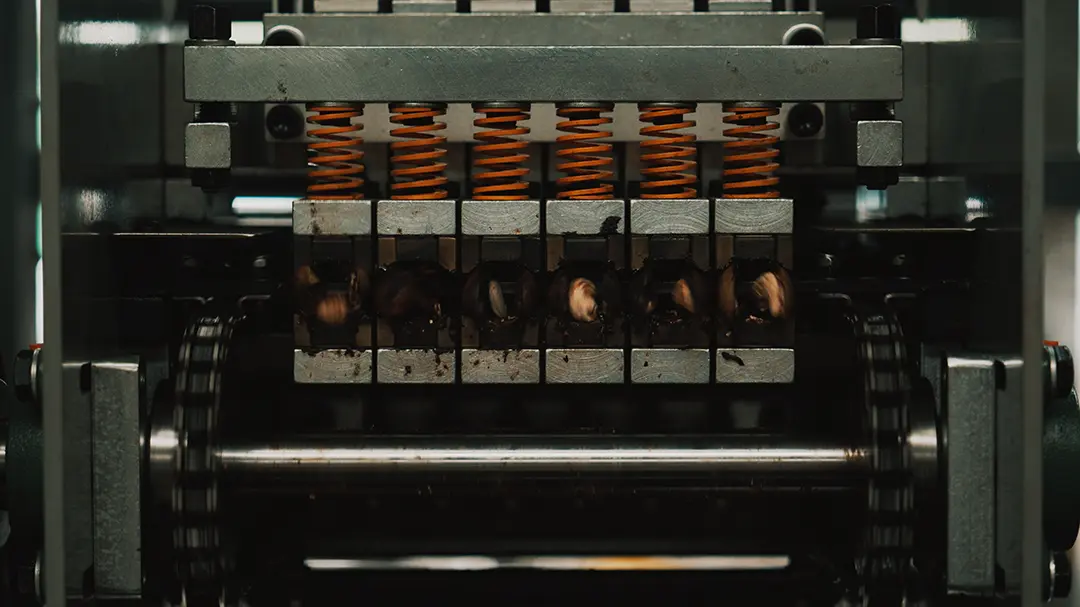

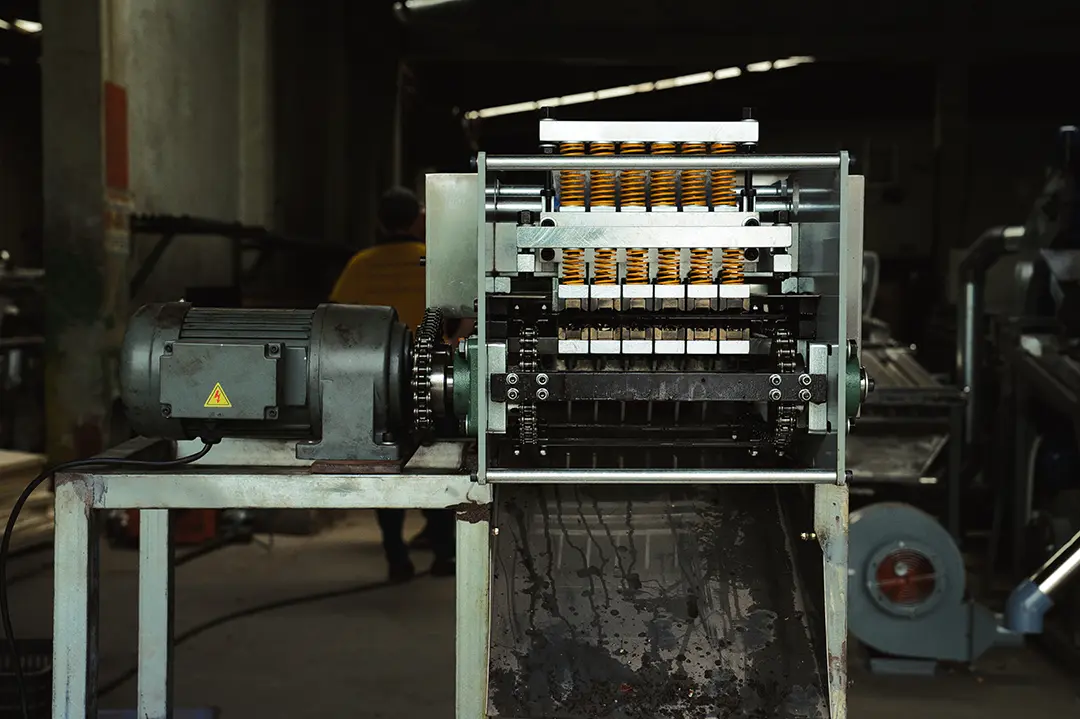

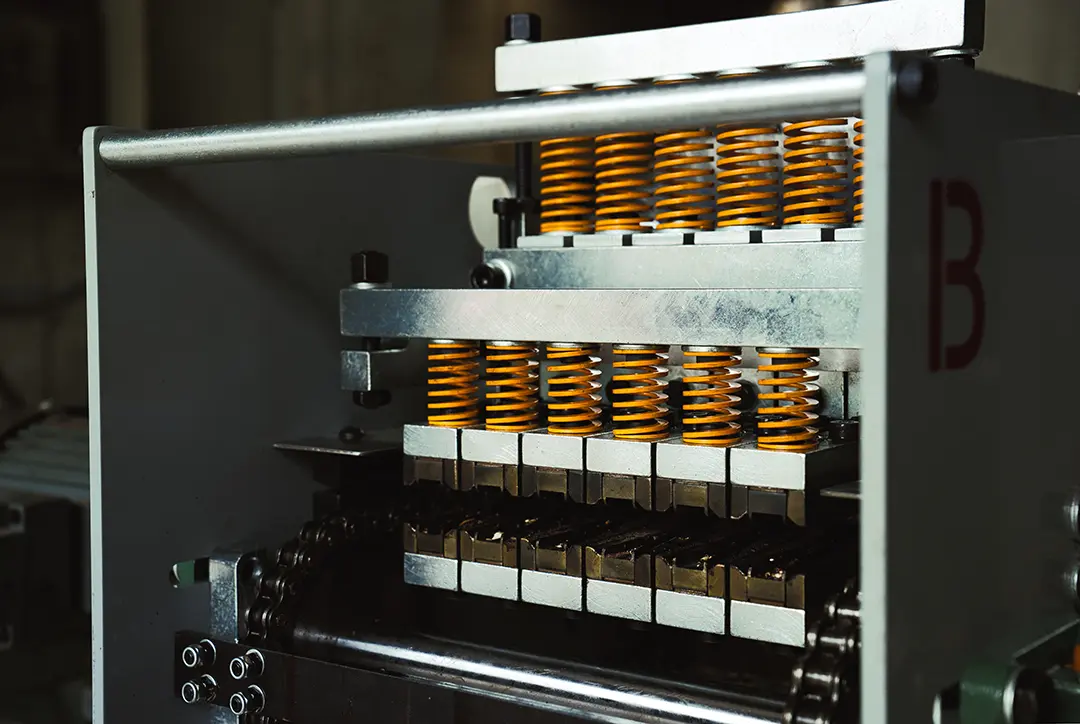

A cashew cutting machine typically consists of a feeding system, cutting blades, a separation mechanism, and a collection tray. The feeding system ensures a steady supply of nuts to the blades, which precisely cut the shells without damaging the kernels. The separation mechanism then efficiently separates the shells from the kernels, which are collected in a tray for further processing.

Benefits of Using a Cashew Cutting Machine

Enhanced Efficiency in Cashew Processing

One of the primary advantages of using a cashew cutting machine is the significant boost in processing efficiency. These machines can handle large volumes of cashews, significantly reducing the time required to cut and shell the nuts compared to manual methods.

Improved Quality and ConsistencyUniformity is critical in cashew processing. Cashew cutting machines ensure that each nut is cut precisely, resulting in a consistent product quality. This uniformity is challenging to achieve with manual cutting, where variations in human skill can lead to inconsistent results.

Cost-Effectiveness and Labor Savings

While the initial investment in a cashew cutting machine may be substantial, the long-term benefits far outweigh the costs. The reduction in labor expenses and the increase in processing speed contribute to overall cost savings. Additionally, the reduced need for skilled labor makes these machines an attractive option for cashew processors.

Types of Cashew Cutting Machines

Manual Cashew Cutting Machines

Manual machines are the simplest and most cost-effective option. They require human operation but provide greater control over the cutting process. These machines are suitable for small-scale operations where budget constraints are a consideration.

Semi-Automatic Cashew Cutting Machines

Semi-automatic machines bridge the gap between manual and fully automated systems. They automate parts of the process while still requiring some human intervention. These machines offer a balance between cost and efficiency, making them ideal for medium-scale operations.

Fully Automatic Cashew Cutting Machines

Fully automatic machines represent the pinnacle of cashew cutting technology. They automate the entire process, from feeding the nuts to cutting and separating the kernels. These machines are the most efficient and are best suited for large-scale operations where high volume and consistency are paramount.

How Cashew Cutting Machines Work

The Cutting Process Explained

Cashew cutting machines use specialized blades to slice through the tough outer shell of the cashew nut without damaging the kernel inside. The nuts are fed into the machine, where they are aligned for precise cutting. The blades are designed to make clean cuts, ensuring that the kernels remain intact.

Safety Measures in Cashew Cutting Machines

Modern cashew cutting machines are equipped with various safety features to protect operators. These include protective shields, emergency stop buttons, and automated shut-off mechanisms that activate if a malfunction is detected. These safety measures are crucial in preventing accidents and ensuring smooth operation.

Key Features to Look for in a Cashew Cutting Machine

Precision and Accuracy

The precision of the cutting mechanism is a critical factor in determining the quality of the end product. Machines with high-precision blades ensure that each cut is clean and consistent, preserving the integrity of the kernels.

Durability and Build Quality

Investing in a machine built with high-quality materials ensures longevity and reliable performance. Durable machines can withstand the rigors of continuous operation, reducing downtime and maintenance costs.

Ease of Maintenance and Cleaning

Maintenance is an important aspect of ensuring the longevity of a cashew cutting machine. Machines that are easy to disassemble and clean help in maintaining hygiene standards and prevent contamination of the kernels.

There are no reviews yet.