Description

The cashew industry is a vital sector in the agricultural domain of many tropical countries, contributing significantly to their economies. With the increasing demand for cashews in global markets, there is a pressing need for more efficient processing methods. This blog post explores the role of cashew shelling machines, which are pivotal in automating the labor-intensive process of breaking open cashew nuts to extract the edible kernels. This introduction sets the stage for a detailed examination of cashew shelling machines, from their history to the latest technological advancements.

History of Cashew Shelling

The history of cashew shelling is as fascinating as the nut itself, originating from the coastal areas of northeastern Brazil and spreading globally as a valuable commercial product. Initially, cashew nuts were shelled manually by local workers using simple tools like hammers or stones, which was not only labor-intensive but also inefficient, leading to high rates of kernel damage.

As the demand for cashews grew, the need for more efficient methods became apparent. The mid-20th century saw the first mechanical solutions designed to crack the tough outer shell without damaging the delicate kernel inside. These early machines were basic and required significant manual intervention, but they marked a significant step forward in industrial cashew processing.

Through the decades, technological advancements have greatly improved the efficiency and effectiveness of cashew shelling machines. Today, these machines combine the precision of modern engineering with sophisticated software to ensure high yields and minimal kernel damage, reflecting a long journey of innovation and adaptation.

Types of Cashew Shelling Machines

Manual Cashew Shelling Machines

Description and How They Work: Manual cashew shelling machines are the simplest form of mechanical shelling solutions. Operated by hand, these machines usually feature a lever mechanism where the operator places a nut and pulls a lever to apply force, cracking the shell. This method is more controlled compared to traditional hand shelling but still relies heavily on human labor.

Pros and Cons:

- Pros:

- Low cost and easy to maintain.

- Suitable for small-scale operations.

- Cons:

- Labor-intensive and slow.

- Higher rates of kernel damage compared to more automated systems.

Semi-Automatic Cashew Shelling Machines

Description and How They Work: Semi-automatic shelling machines reduce the need for manual labor by automating parts of the shelling process. These machines typically require an operator to place the nuts in position, but the actual cracking is done mechanically, often timed or triggered by a sensor.

Pros and Cons:

- Pros:

- Faster than manual machines.

- Less physically demanding.

- Cons:

- Initial cost is higher than manual machines.

- Requires some manual handling.

Fully Automatic Cashew Shelling Machines

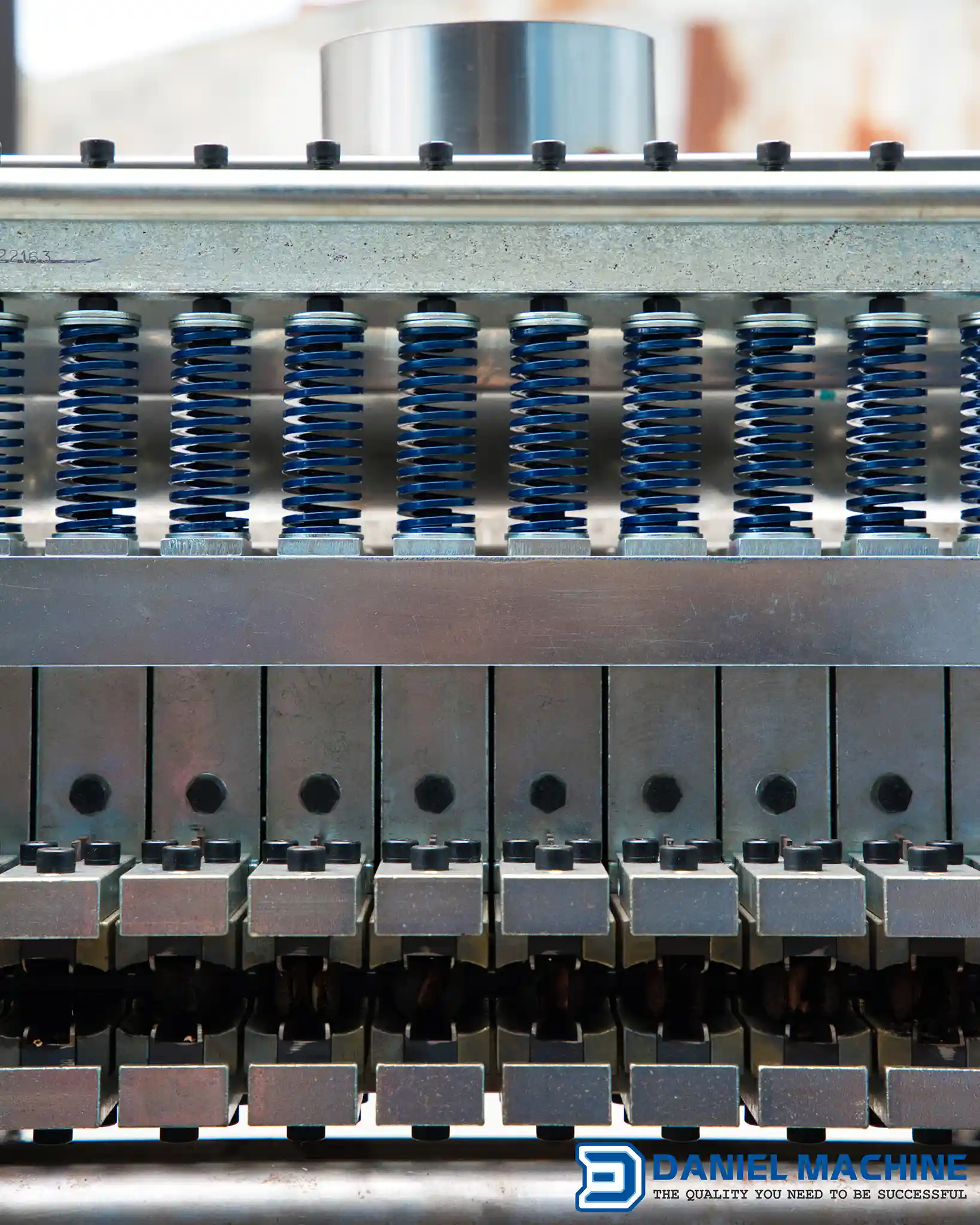

Description and How They Work: Fully automatic machines represent the pinnacle of cashew processing technology. These systems use advanced sensors and algorithms to position each nut precisely, applying the optimal force to shell the nut without damaging the kernel. Integration with conveyor systems allows for continuous processing, significantly increasing throughput.

Pros and Cons:

- Pros:

- High efficiency and large volume processing.

- Minimal manual labor required.

- Consistent kernel quality with low damage rates.

- Cons:

- High initial investment and maintenance cost.

- Complex setup and operational requirements.

How Cashew Shelling Machines Work

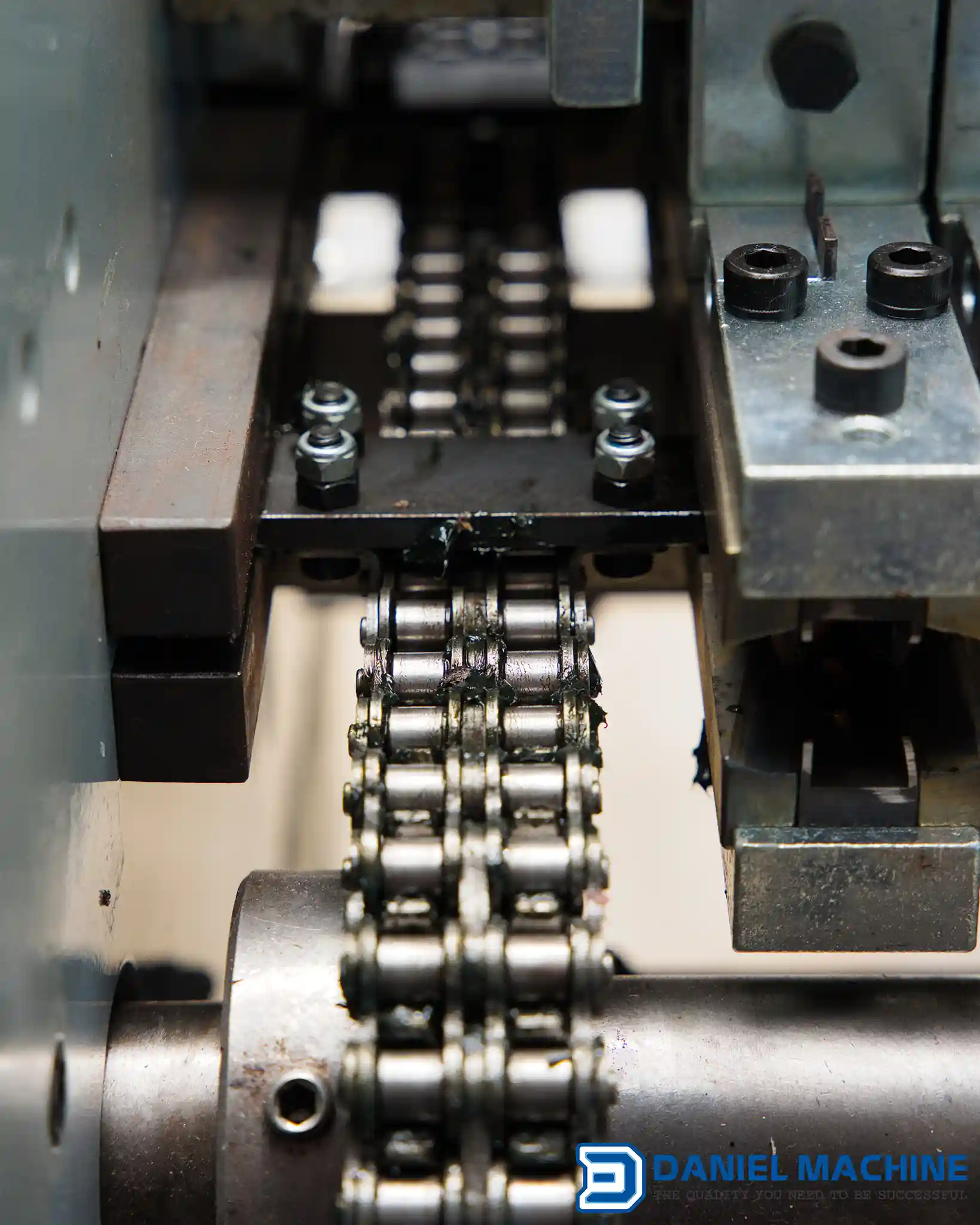

The operation of cashew shelling machines, whether manual, semi-automatic, or fully automatic, involves several key steps designed to preserve the integrity of the cashew kernel while efficiently removing the hard outer shell.

Step-by-Step Process Description:

- Feeding: Cashews are fed into the machine either manually or via an automated feeding system.

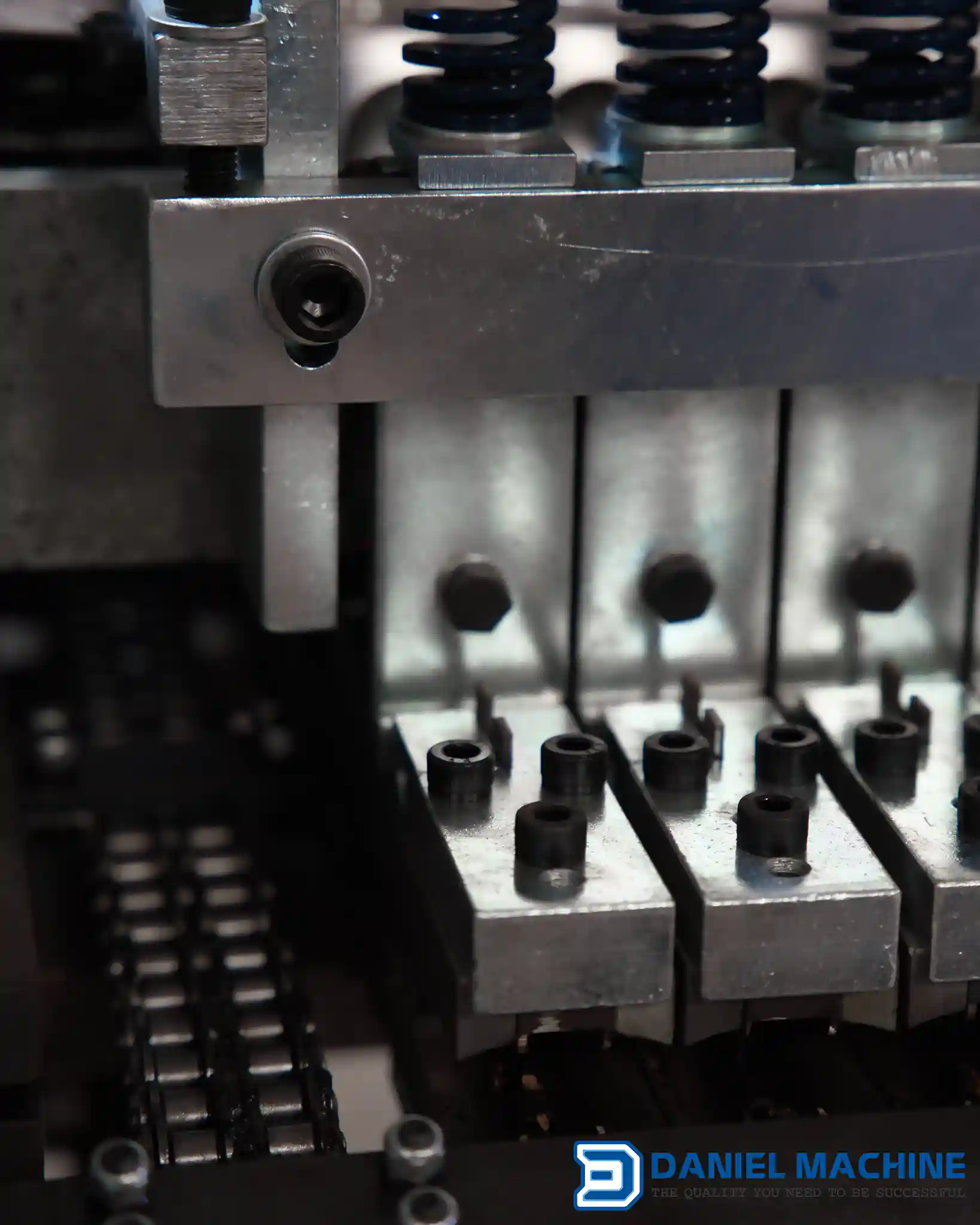

- Orientation: Sensors or mechanical systems orient the cashew nut so that the force is applied optimally.

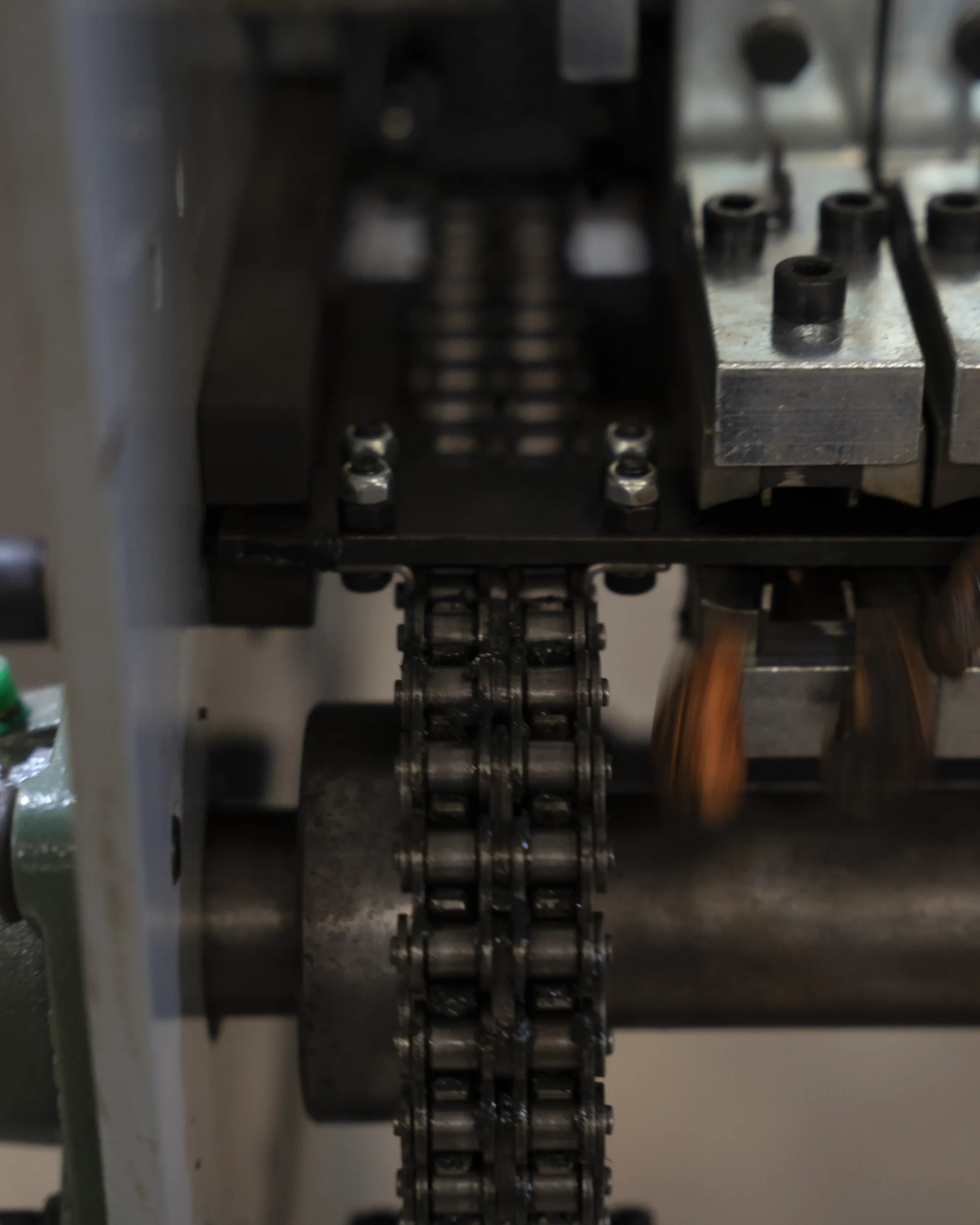

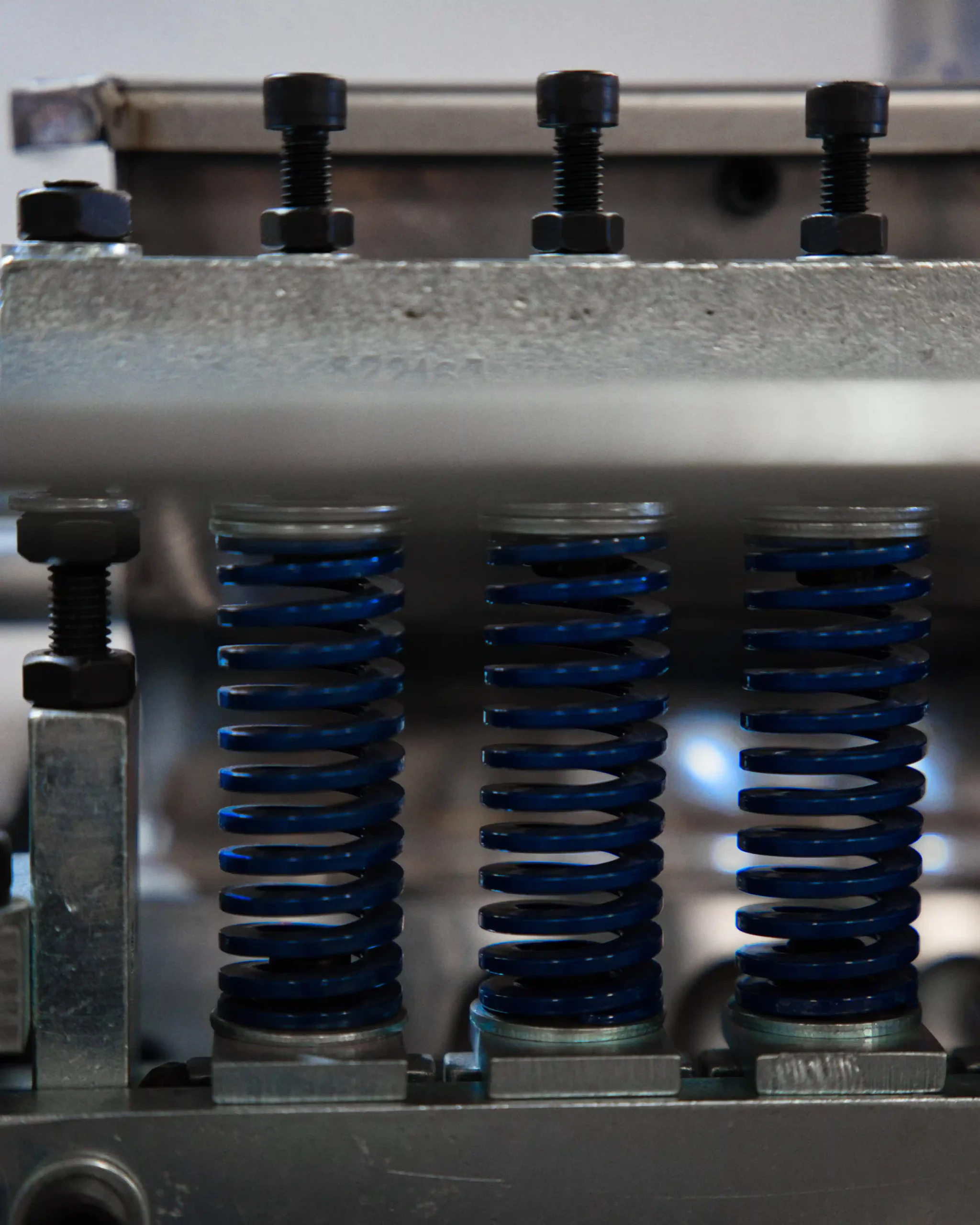

- Shelling: A controlled force is applied to crack the shell. This may involve blades, rollers, or hydraulic mechanisms, depending on the machine type.

- Separation: The shells are separated from the kernels. Some advanced machines incorporate blowers or vibration systems to aid this separation.

Technologies Involved:

- Hydraulics and Pneumatics: These provide the necessary force to crack the tough outer shells.

- Sensors: Used especially in automated machines to ensure each nut is positioned correctly to minimize damage.

- Integration: Most advanced machines are part of an integrated system that includes sorting and peeling, further automating the cashew processing line.

Benefits of Using Cashew Shelling Machines

The adoption of cashew shelling machines brings significant benefits to the cashew processing industry, impacting efficiency, labor costs, and product quality.

Increased Efficiency and Throughput: Shelling machines, particularly the fully automatic types, can process cashews at a much faster rate than manual methods. This high throughput is essential for meeting the growing global demand for cashews, ensuring that processors can handle large volumes efficiently during peak seasons.

Reduction in Labor Costs and Manual Labor: Automated shelling machines reduce the reliance on manual labor, which is not only costly but also inconsistent. By automating the shelling process, companies can allocate their human resources to more critical areas of the production line, such as quality control and packaging, where human expertise is invaluable.

Improvement in Kernel Quality and Reduction in Damage: One of the key advantages of using shelling machines is the consistent quality of the output. Advanced machines are designed to minimize kernel damage, which is crucial for maintaining the aesthetic and nutritional quality of cashews—a significant factor in market pricing.

Challenges and Solutions

While cashew shelling machines offer numerous benefits, they also come with their own set of challenges, which can impact their efficiency and effectiveness.

Mechanical Failures and Maintenance Issues: Like any mechanical system, cashew shelling machines are prone to wear and tear, leading to breakdowns that can disrupt production.

- Solution: Regular maintenance and timely replacement of worn-out parts are essential. Investing in high-quality machines and training maintenance staff can minimize downtime.

Training for Machine Operation: Fully automatic shelling machines involve complex operations that require skilled personnel.

- Solution: Implementing comprehensive training programs for operators ensures that they are well-versed in the nuances of the machines, leading to better handling and fewer operational errors.

Adaptation to Different Sizes and Shapes of Cashews: Cashews are natural products, and their size and shape can vary significantly, which can be challenging for standard machines.

- Solution: Advanced machines with adaptive technologies that can adjust to different sizes and shapes of cashews are increasingly becoming popular. These machines use sensors and adaptive mechanisms to modify the shelling process dynamically.

Future of Cashew Shelling Technology

The future of cashew shelling technology looks promising, with continuous advancements aimed at improving efficiency, sustainability, and adaptability.

Innovations in Automation and Robotics: Future cashew shelling machines are likely to incorporate more advanced robotics and AI to further reduce the need for human intervention, increasing precision in the shelling process.

Sustainable Practices and Energy Efficiency: As the global focus on sustainability intensifies, future developments in cashew shelling technology will also emphasize energy efficiency and the use of renewable energy sources to power the machines.

Market Trends and Industry Growth Forecasts: The cashew market is expected to continue its growth trajectory, driven by increasing consumer demand for healthy snack options. This growth will spur further innovations in shelling technology, with manufacturers likely to invest in research and development to gain a competitive edge.

Conclusion

Cashew shelling machines have revolutionized the cashew processing industry, bringing unparalleled efficiency and substantial improvements in product quality. From manual devices to sophisticated automated systems, these machines have evolved significantly, reflecting the industry’s advancements. The future holds promising prospects with the integration of more sophisticated technologies, making the process even more efficient and sustainable. As we look ahead, it is clear that technological advancements will continue to play a crucial role in shaping the cashew industry, benefiting producers and consumers alike.

There are no reviews yet.